In the world of industrial machinery and plastic processing equipment, screw barrels significantly influence decisions aimed at improving efficiency, uniformity, and product quality. These articles form the conditional layers, so to speak, for different plastic extrusion and injection moulding machines. India, being one of the world’s leading engineering hubs, has likely emerged as a major centre for the production and export of screw barrels. In particular, screw barrel manufacturers in India have gained worldwide recognition for their engineering excellence, innovative manufacturing capabilities, and solid global supply chains.

In this detailed blog, we will go through every step a screw barrel manufacturer in India carries out while paying special focus on operations conducted by any prominent screw barrel manufacturers in Ahmedabad, a city recognized as a creation stronghold.

Understanding Screw Barrels: Function & Importance

Before we examine the manufacturing of screw barrels, let’s first define what they are and why they are functionally important.

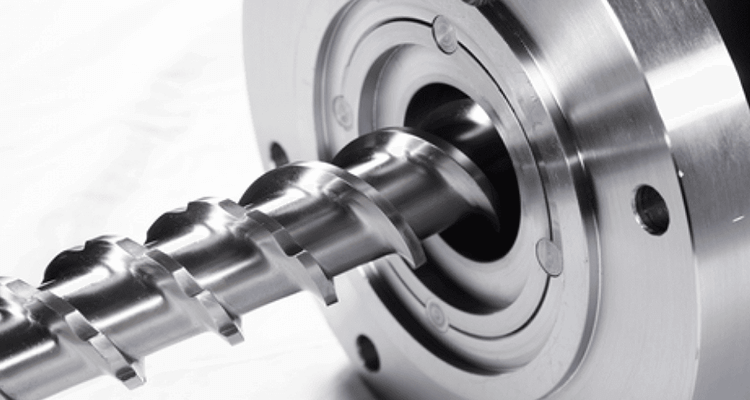

A screw barrel is a vital mechanical part in machines used for transforming plastic (extrusion or injection moulding). A screw barrel is basically a rotating screw within a stationary barrel, where plastic material moves through the rotating screw, melting, mixing, and building a pressure head before it is moulded or extruded into a finished part.

Main functions of a screw barrel:

- Feeding and conveying plastic material.

- Melting and Homogenizing.

- Pressurizing and pumping melted plastic.

- Providing the final part’s consistency and quality.

Nothing else produces a screw barrel fit with precision design, so nothing else is capable of optimal processing in the plastic processing machines. This calls attention to the essential role of the screw barrel manufacturer in modern industry.

Step-by-Step Manufacturing Process by Screw Barrel Manufacturers in India

When it’s about the manufacturing of screw barrels, there is a detailed procedure that needs to be followed, from raw material procurement to inspection of the finished product and dispatch.

1. Raw Material Selection & Procurement

The first and most important step is planning for raw materials and, at the same time, buying the top-grade materials needed. Choice of material will give wear resistance, corrosion resistance and less effect on the life of the screw barrel.

Types of materials that are mostly used:

- Nitrided steel (such as 38CrMoAlA)

- Bimetallic alloys

- Tool steels for some higher specification applications

Most Indian manufacturers must be considering certified suppliers so as to preserve good mechanical strength and chemical integrity.

Want to Know the Best Material for Your Extrusion Machine?

Contact a certified screw barrel manufacturer in Ahmedabad today for a free consultation!

2. Precision Forging or Casting

After choosing the material, the metal is forged or cast into rough cylindrical shapes. Forging provides better grain flow, which improves the metal’s strength and durability.

At this stage, the diameter will be larger than needed, allowing for fine machining to be performed later in the process.

3.Heat Treatment (Nitriding, Induction Hardening, etc.)

Heat treatment is undertaken to improve hardness, wear resistance, and durability. A typical screw barrel manufacturer in India may use one or more of the following processes:

- Nitriding: Diffuses nitrogen into the very outer layer to improve hardness.

- Induction Hardening: Performs selective hardening on localized areas of interest.

- Quench & Tempering: Increases toughness and mechanical strength to the screw barrel.

This step is critical to achieving the best performance when operating under high-stress conditions.

4. CNC Machining & Turning

After hardening, the screw barrel will be CNC-machined to impart the component’s geometry and surface finish.

Some key CNC processes are:

- Turning

- Milling

- Threading

- Grooving

Utilizing advanced CNC machines allows tolerances within microns, which is essential to provide the optimal screw-to-barrel clearance.

Precision Matters. Looking for CNC-Machined Screw Barrels?

Partner with top exporters of screw barrels from India for unmatched quality.

5. Screw Geometry Design & Customization

The construction of the screw geometry (e.g. compression ratio, screw pitch and flight depth) is contingent upon the polymer that is being processed and the application to be used.

Screw barrel manufacturers in Ahmedabad will provide you with custom-designed screw barrels based upon:

- Type of polymer (HDPE, LDPE, PVC, etc.)

- Rate of output

- Type of machine (extruder, injection moulding, blow moulding)

By customizing your package in terms of screw barrel geometry it helps improve the efficiency of plasticizing polymer and the total energy consumption of the machine.

5. Surface Coating & Plating

Once the barrel is machined, it then goes through surface enhancement processes to improve the wear and corrosion resistance of the surface area.

Some common coatings are:

- Hard chrome plating

- Tungsten carbide coating

- Bimetallic lining (common for barrels)

These surface treatments help with extended use of the component, particularly when being used for abrasive or corrosive materials.

6. Quality Control & Dimensional Inspection

Quality control is an absolute must. The top screw barrel manufacturers in India have their own quality departments with the following technology:

- Coordinate Measuring Machines (CMM)

- Hardness testers

- Ultrasonic flaw detection

- Profile projectors

Every stage in the process is executed with inspection quality control procedures to ensure that the final product meets the given international standards (ISO, DIN, or ASTM).

Quality is Our Promise.

Ask for a free inspection report sample from a trusted screw barrel manufacturer in Ahmedabad today!

7. Assembly & Pair Matching

In twin screw configurations, “pairing” is essential. Each screw and barrel pair must fit exactly with its partner in order to minimize wear and provide uniform output.

Screw barrels are combined and checked for:

- Concentricity

- Parallelism

- Smooth rotation

- Backlash clearance

Pair matching is a key quality control step for exporters of screw barrels who supply their international customer base with high-performance screw barrels.

8. Trial Run & Performance Testing

In preparation for delivery, trial runs may be performed to duplicate the working conditions of the screw barrel. This runs, in whole or in part, will identify thermal expansion issues, material flow properties, torque loading testing or lubrication effectiveness.

To some degree, those suppliers who export to some consumption markets in Europe, the USA, and Southeast Asia may see trial runs incorporated into their process.

Looking For a Proven & Tested Solution for Your Screw Barrel Needs?

Buy from leading exporters of screw barrels in India as a viable and reliable alternative for your company, for peace of mind and performance.

9. Surface Finishing, Marking & Packaging

The last stage in finishing a screw barrel relates to:

- Polishing for appearance and to improve corrosion resistance.

- Laser marking to identify the part and traceability for warranty.

- Export grade packaging (anti-rust oils and coatings, wooden crates, vacuum sealed type bags)

The surface treatment of these types of screw barrels is designed to ensure they arrive at your location in perfect condition.

Why Ahmedabad Is a Hub for Screw Barrel Manufacturing?

The city of Ahmedabad has established a solid position in the engineering sector. Reasons for many international buyers preferring the screw barrel manufacturer in Ahmedabad include, but are not limited to:

- Availability of specialized workers and precision machining applications.

- Port access for easy exports.

- Value-added supply chain (metallurgy, heat treatment, CNC).

- Global standards-compliance and certification.

- Affordable pricing for excellent quality.

Ahmedabad has some of the most reputable exporters of screw barrels in various parts of Europe, South America, Africa, and the Middle East.

Use of Screw Barrels across Multiple Industries

The benefits of screw barrels allow usage in a variety of industrial businesses, such as:

- Plastic extrusion (pipes, sheets, films).

- Injection moulding (automotive, medical devices, consumer products).

- Packaging (food, pharmaceutical).

- Rubber processing

- Recycling thermoplastics

Each of these sectors requires its specific configuration for the application, and connecting with a reputable screw barrel manufacturer in India is very important for the application’s performance.

How to Choose the Right Screw Barrel Manufacturer in India?

If you’re considering sourcing from India, here’s a short checklist for assessing the manufacturers:

- Number of years in the business (10+ is ideal).

- Owns CNC and heat-treatment capabilities.

- Understanding of export formation (COO, CE, RoHS).

- Ability to customize and design parts.

- Good client reviews and international practices.

- Post-sale service and warranty.

Conclusion

Screw barrel production is a technical and exciting combination of metallurgy, precision engineering, heat treatment, and quality control. India is a frontrunner because it has an established manufacturing foundation and workforce.

If you are a machine builder, plastic product manufacturer, or OEM, you will appreciate the support provided by screw barrel manufacturers in Ahmedabad, India, for your equipment, uptime, and maintenance. The leading manufacturers from India will provide quality, precision and innovation at the international standard. Additionally, many of these manufacturers are also reputable screw barrel exporters with logistics networks capable of reaching any part of the world safely and quickly.

Don’t Settle for Less.

Schedule a discovery call with a leading screw barrel manufacturer in Ahmedabad and explore how they can enhance your production line.