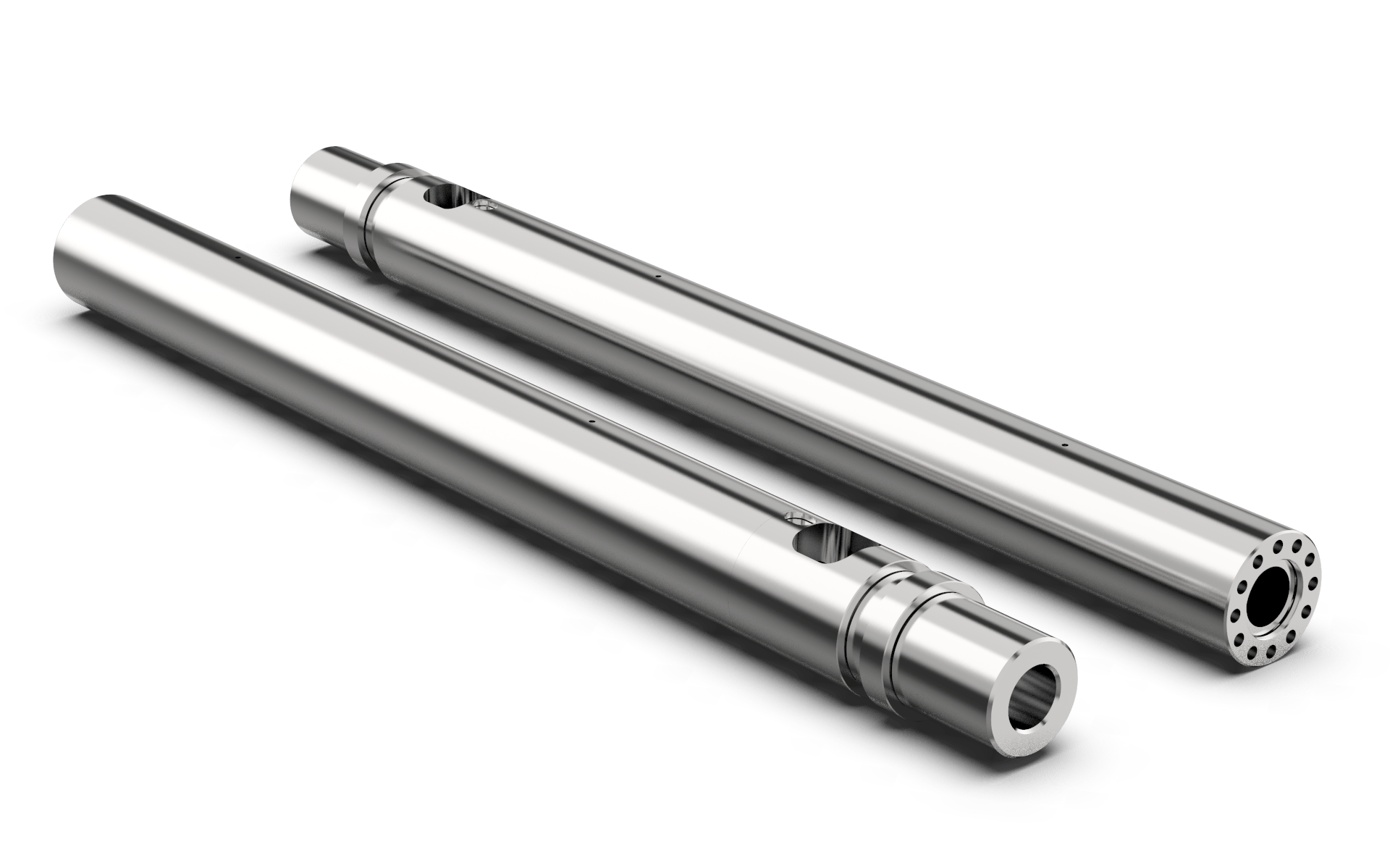

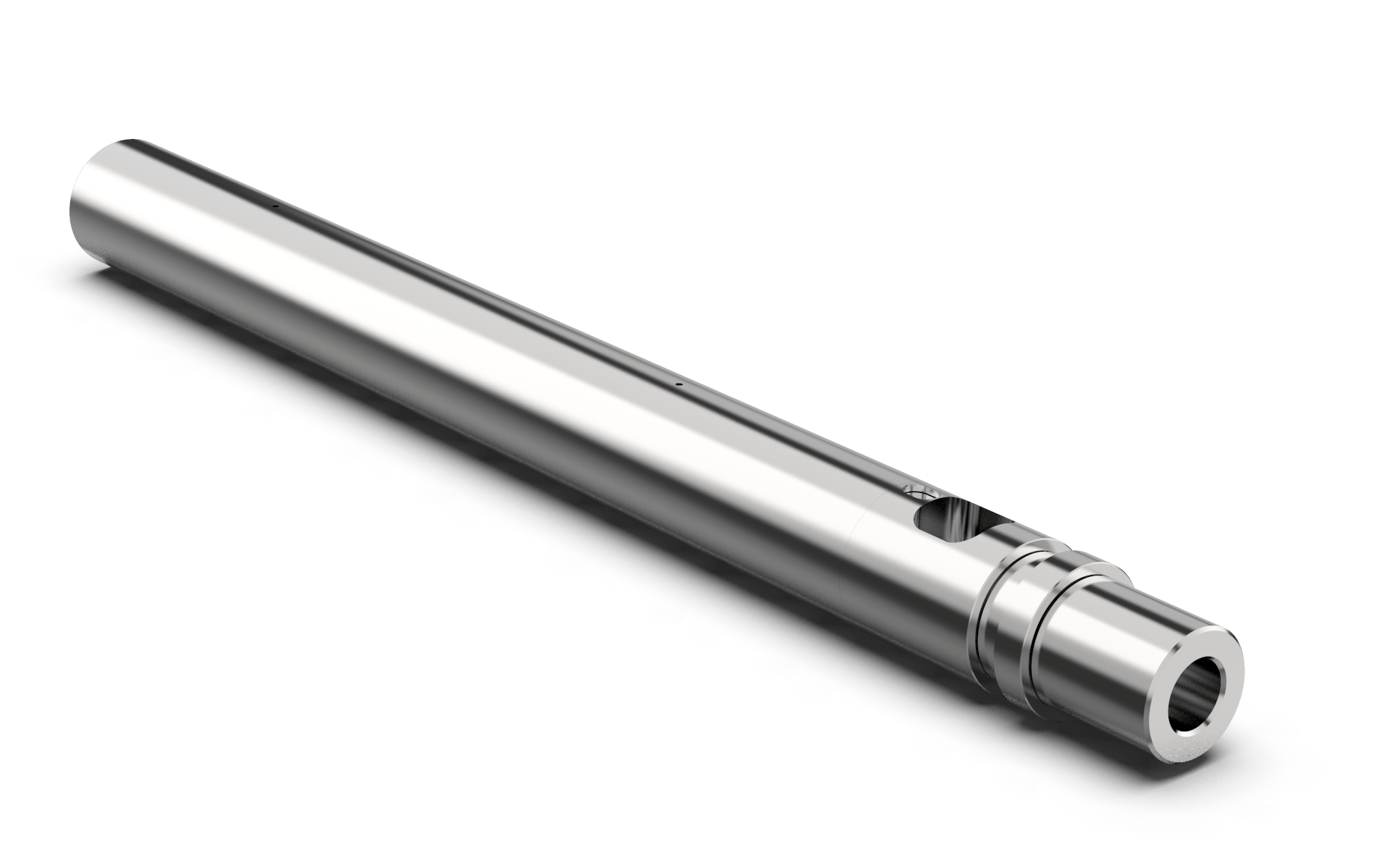

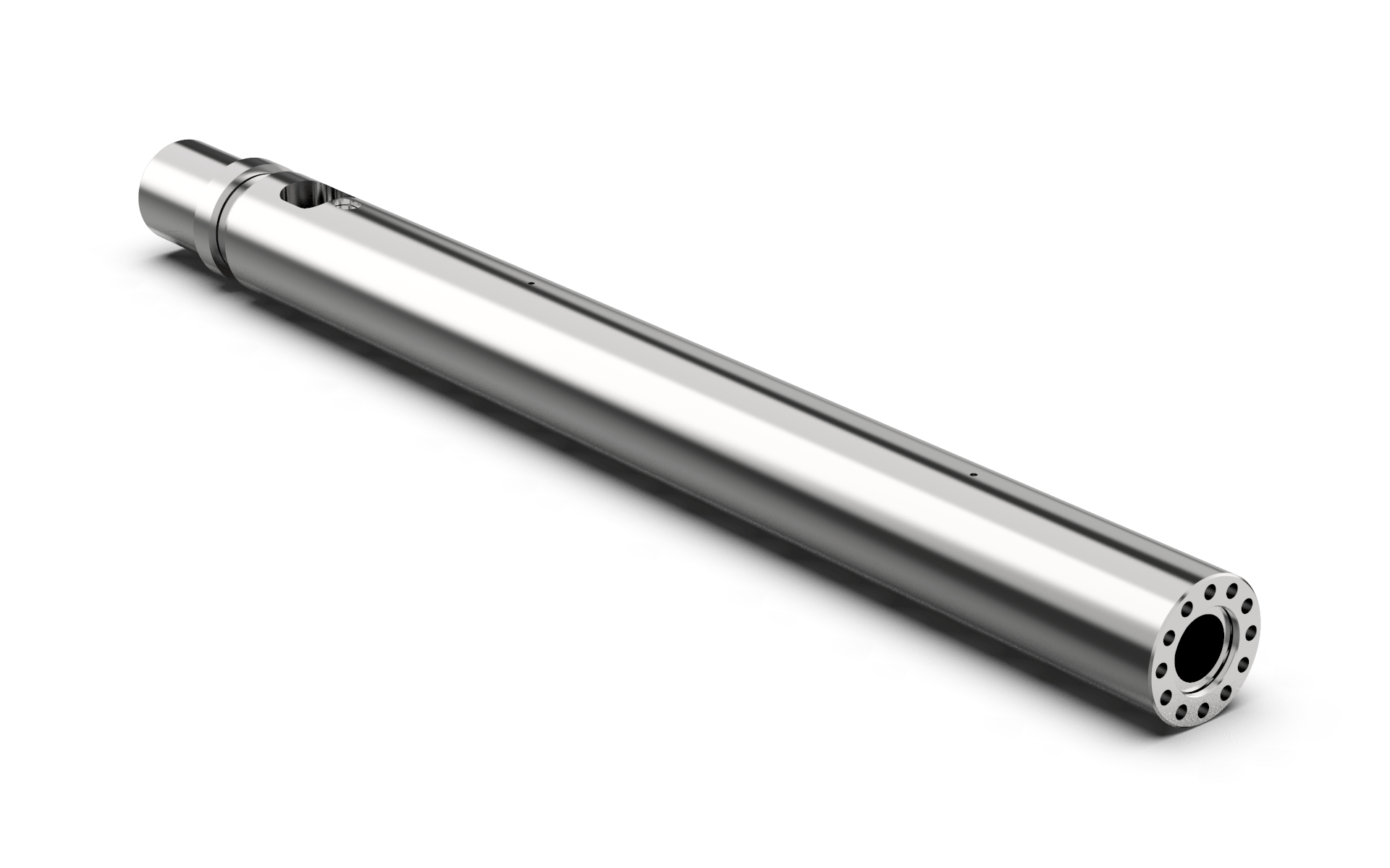

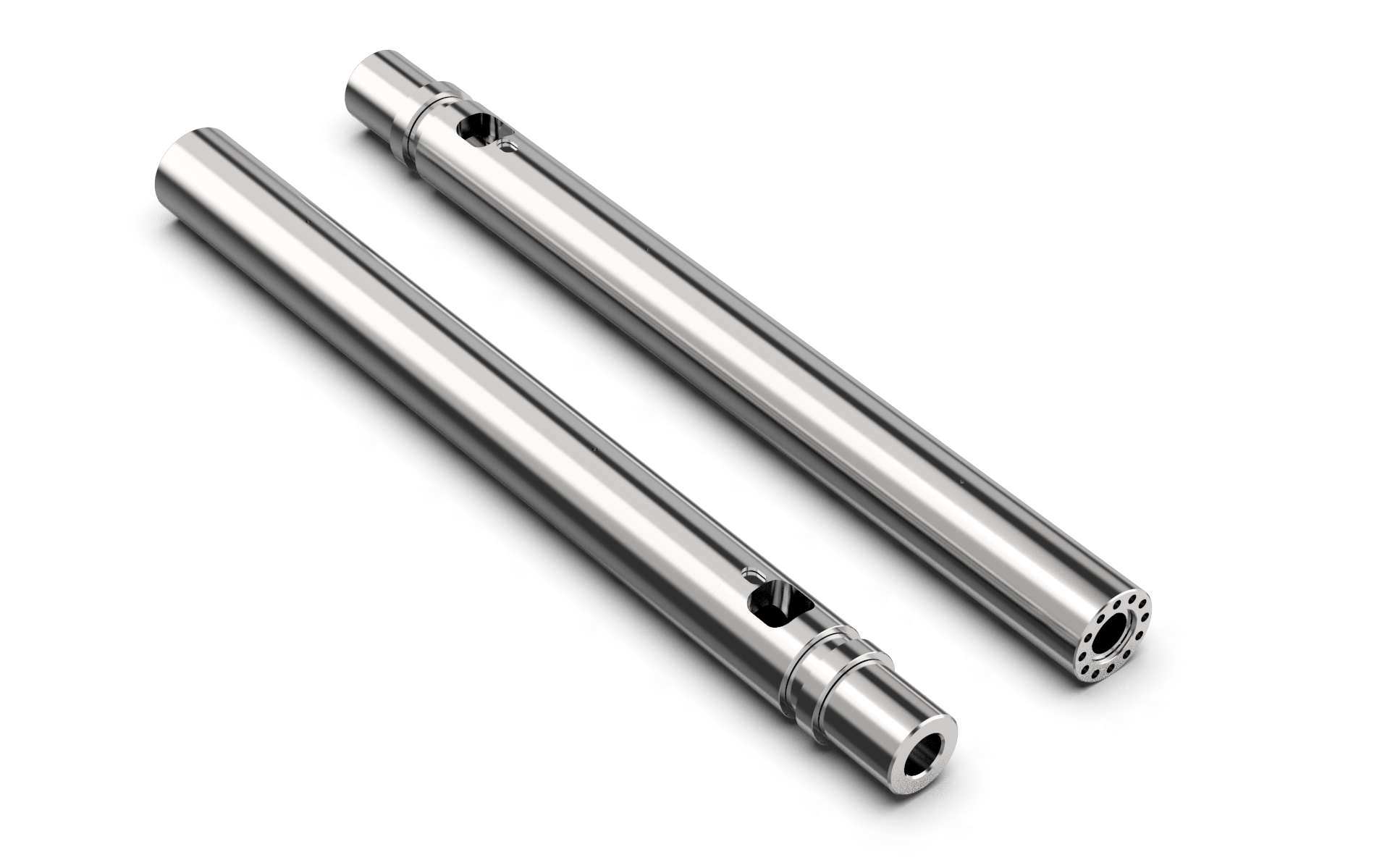

Nitrided Barrel

Nitriding is a heat-treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. A Nitrided Barrel has a plethora of manufacturing capabilities. The applications of Nitrided Barrel are injection molding, extrusion molding, and blow molding. By using high-quality grade nitriding steel, with 72 hours of nitriding process, the nitrided layer will help the barrel to get better performance by being corrosion and abrasion-resistant. Nitrided barrels have a very good wear resistance until the surface the hardness is worn away. The material that is used in a Nitrided Barrel is EN41B and the surface hardness achieved through that is 65-68 HRC. There are multiple sizes available at Shreeji Corporation for the Nitrided Barrel. The sizes available vary from 14mm to 200mm in diameter and the length can go up to 6 meters.

- Product name – Nitrided Barrel

- Material – EN41B

- Available size – Dia 14 – 200 mm, length upto 6m long

- Surface hardness – 62-65 HRC

- Process method – Gas Nitriding

Interested in Nitrided Screw, Bimetallic Screws, HVOF Coat Screw, Hardened Screw, Special Screw Manufacturer, Nitrided Barrel, Bimetallic Barrel, Special Barrel, Tie-Bar, Injection Head, RP Set, Nozzle, Conical Twin Screw & Barrel , Parallel Twin Screw & Barrel Manufacturing? Get Quote.

Production Process

-

Order & drawing confirm

-

Down Payment

-

Production

-

Hardening & Tempering

-

Inspection

-

Documents for clear customs

-

Packing & delivery

-

Balance

-

Inspection

-

Nitriding