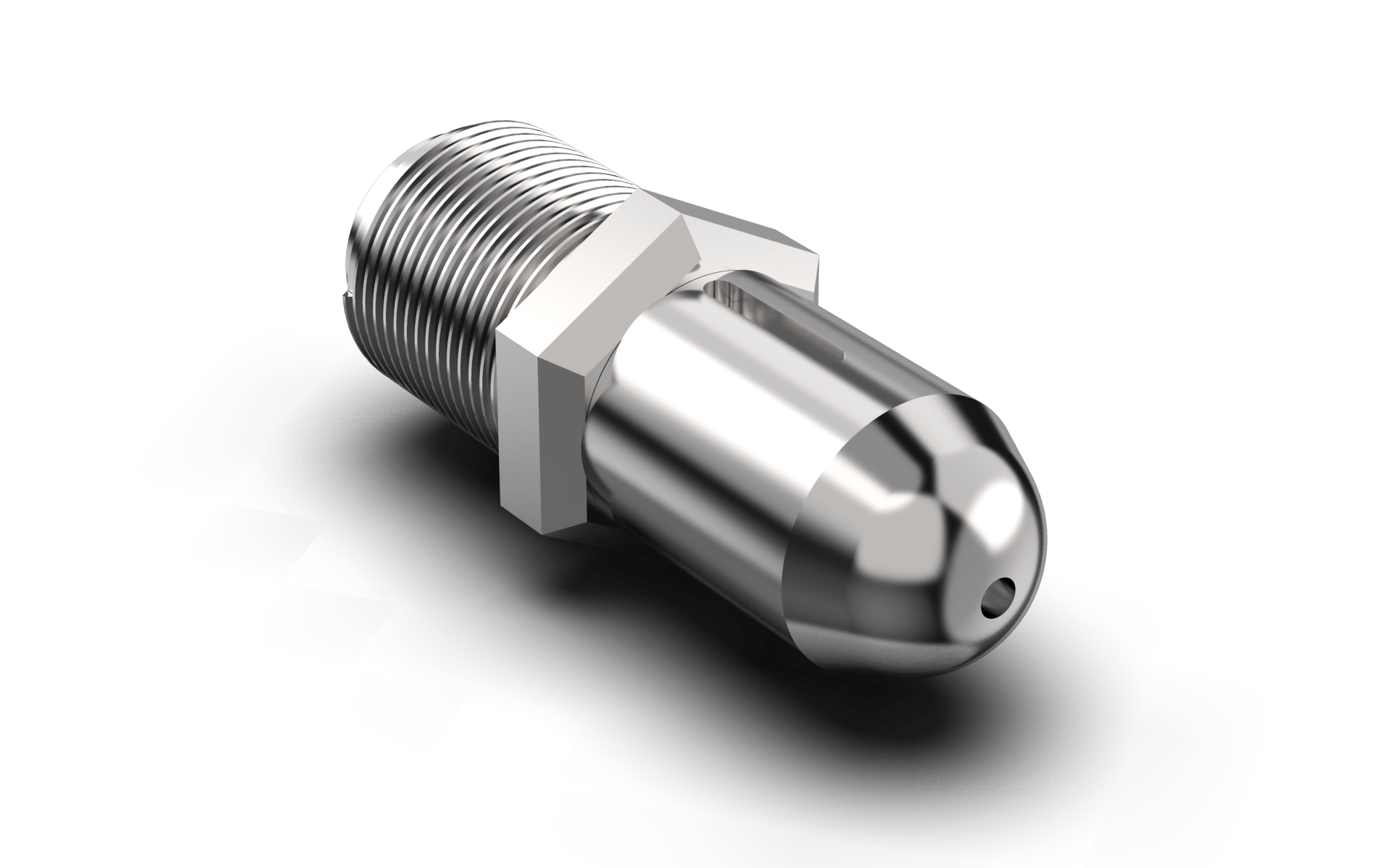

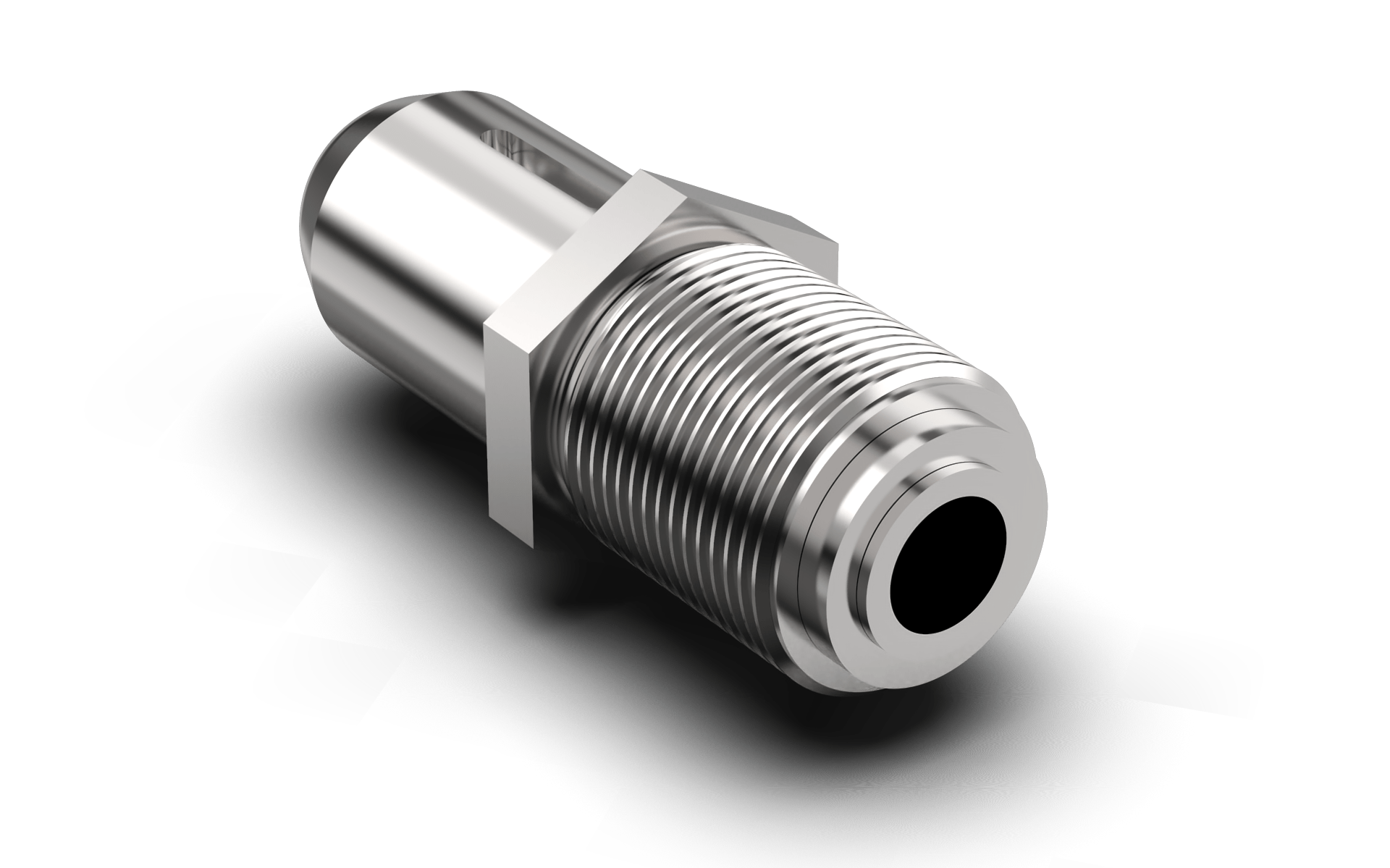

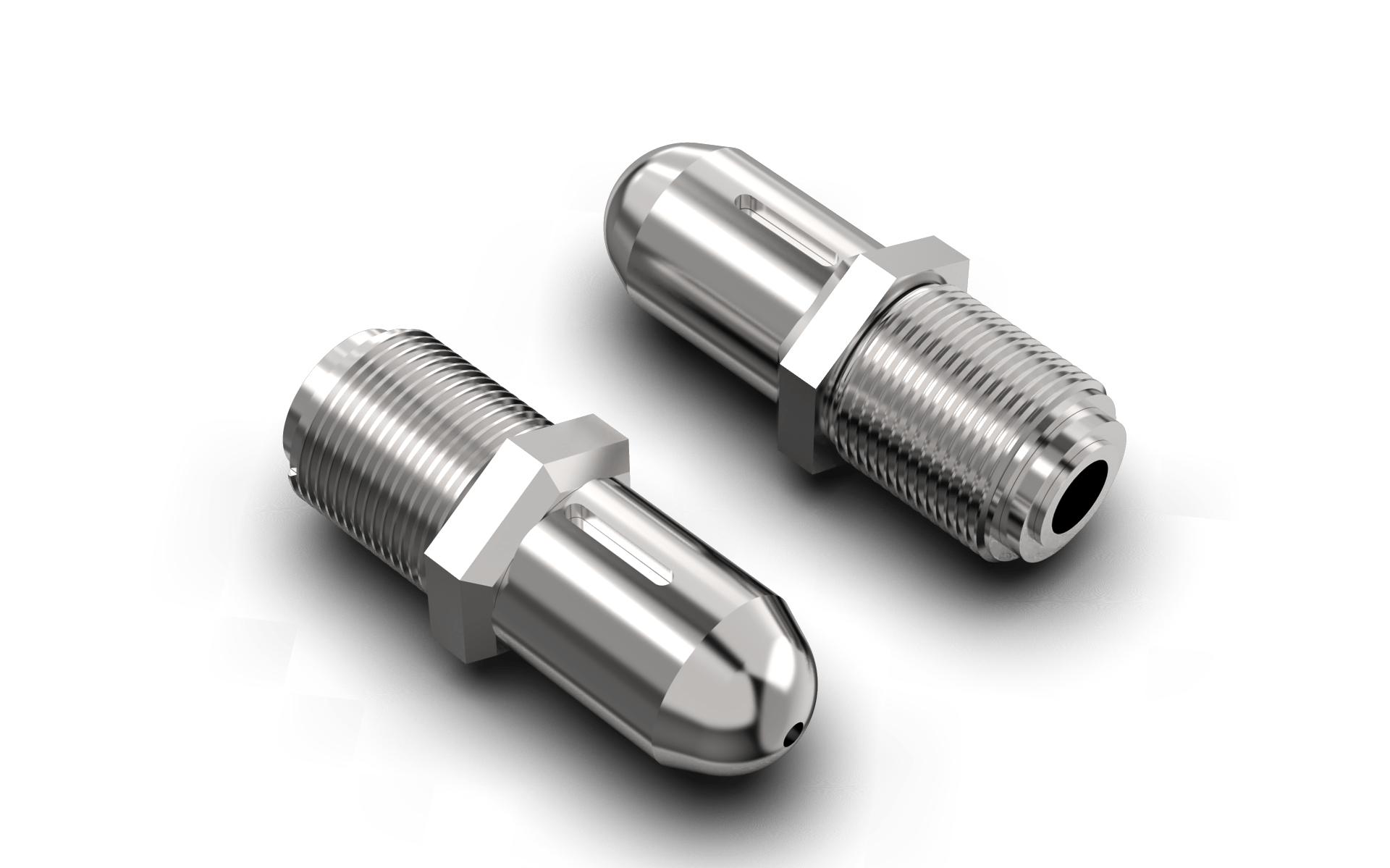

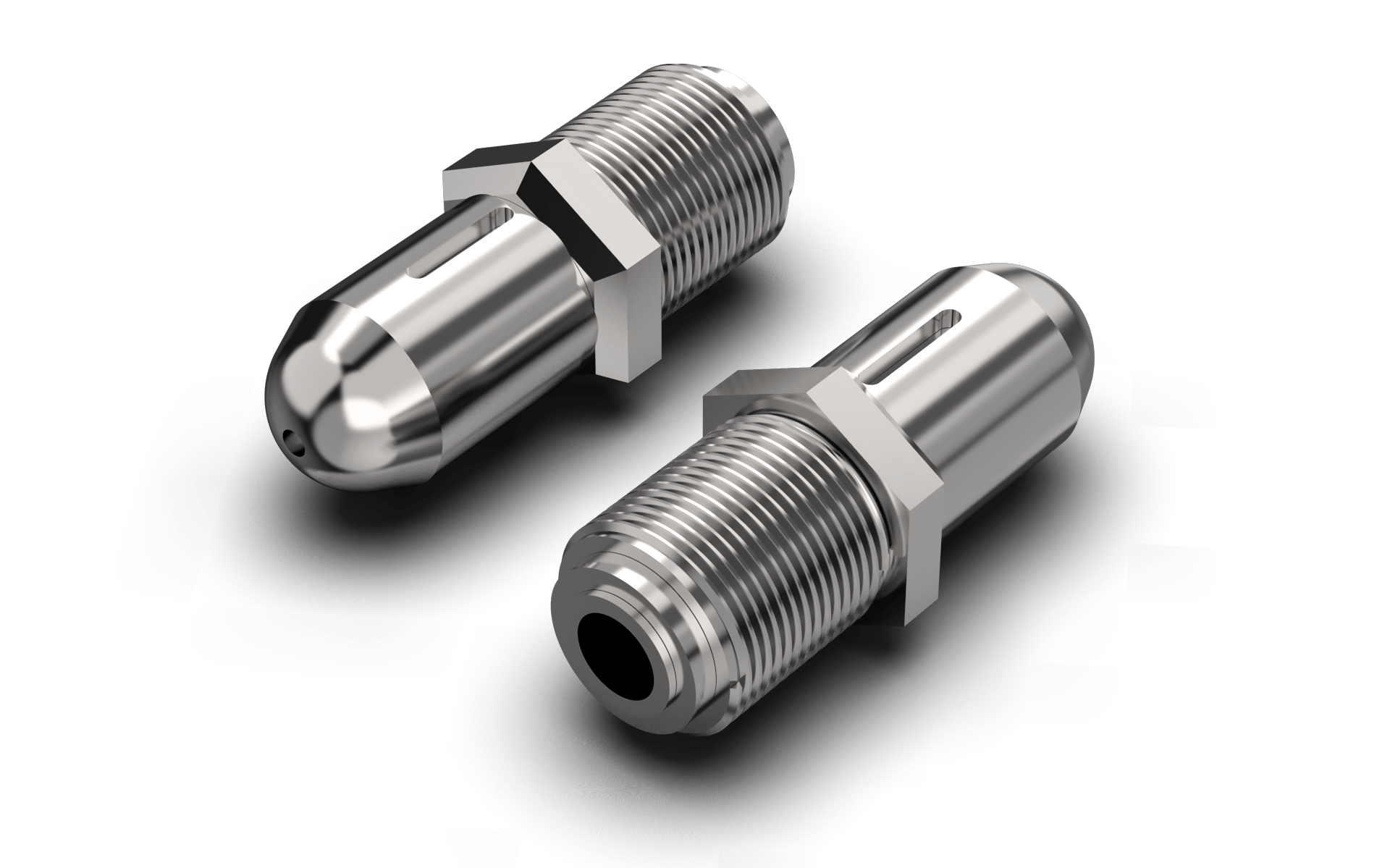

Nozzle

A nozzle should always be hardened for superior life and we make sure that by running it through the gas nitriding process. Nozzles should be reliable with a fine finish and operational fluency. Along with that, nozzles should be easy to install and long-lasting. Other features that a nozzle should have are low maintenance and durability. Nozzles are required in the plastic injection molding manufacturing process. The plasticizing barrel (with reciprocating screw) and the mold are connected by machine shut-off nozzles. Unlike hot runner nozzles, which are installed on the mold side of the plastic injection molding process, they are installed on the machine side. Machine shut-off nozzles vary from open nozzles in that they include a melt channel that can be closed. We at Shreeji Corporation provide effective and highest quality Nozzles for multiple industries, making us the leading Nozzle Manufacturer and Nozzle Exporter in the country. Our Nozzles are one of the best in the country. We make sure that the Nozzles have perfect finishes without any pits, burrs, or rough edges. The material that is used in the manufacturing of Nozzles is EN41B that helps us achieve hardness between 65-68 HRC.

- Product name – Nozzle

- Material – EN41B

- Surface hardness – 65-68 HRC

- Process method – Gas Nitriding

Interested in Nitrided Screw, Bimetallic Screws, HVOF Coat Screw, Hardened Screw, Special Screw Manufacturer, Nitrided Barrel, Bimetallic Barrel, Special Barrel, Tie-Bar, Injection Head, RP Set, Nozzle, Conical Twin Screw & Barrel , Parallel Twin Screw & Barrel Manufacturing? Get Quote.

Production Process

-

Order & drawing confirm

-

Down Payment

-

Production

-

Hardening & Tempering

-

Inspection

-

Documents for clear customs

-

Packing & delivery

-

Balance

-

Inspection

-

Nitriding