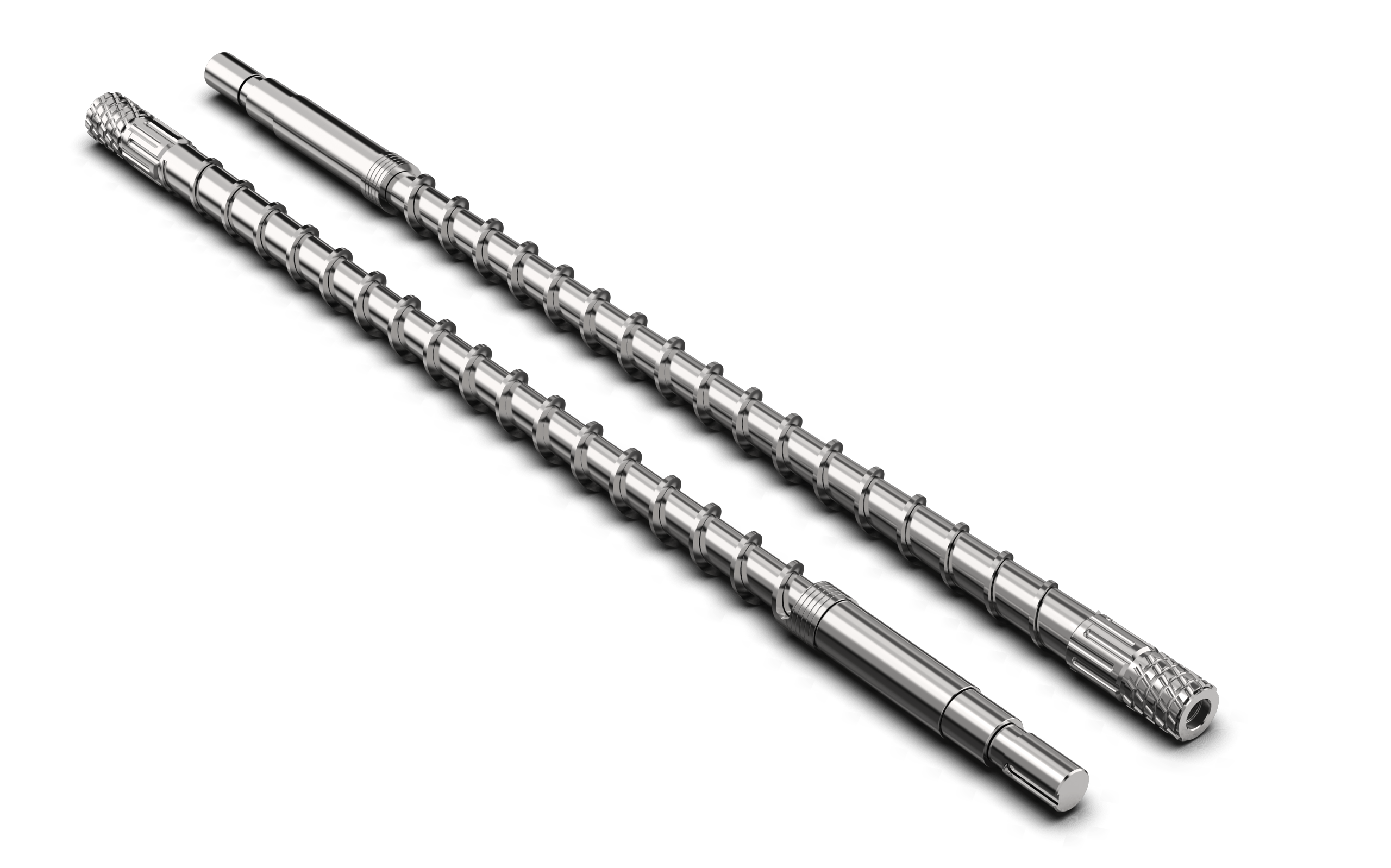

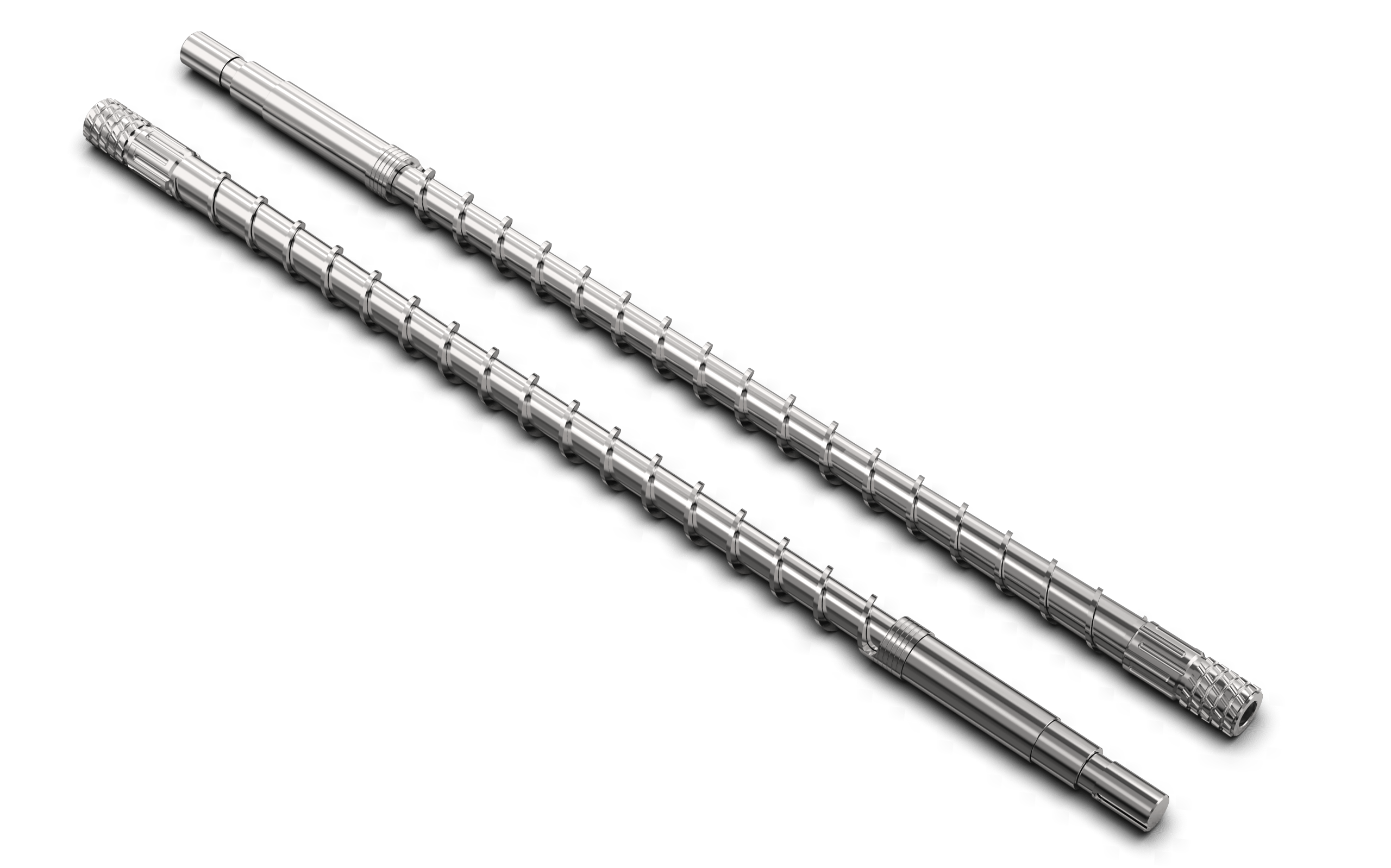

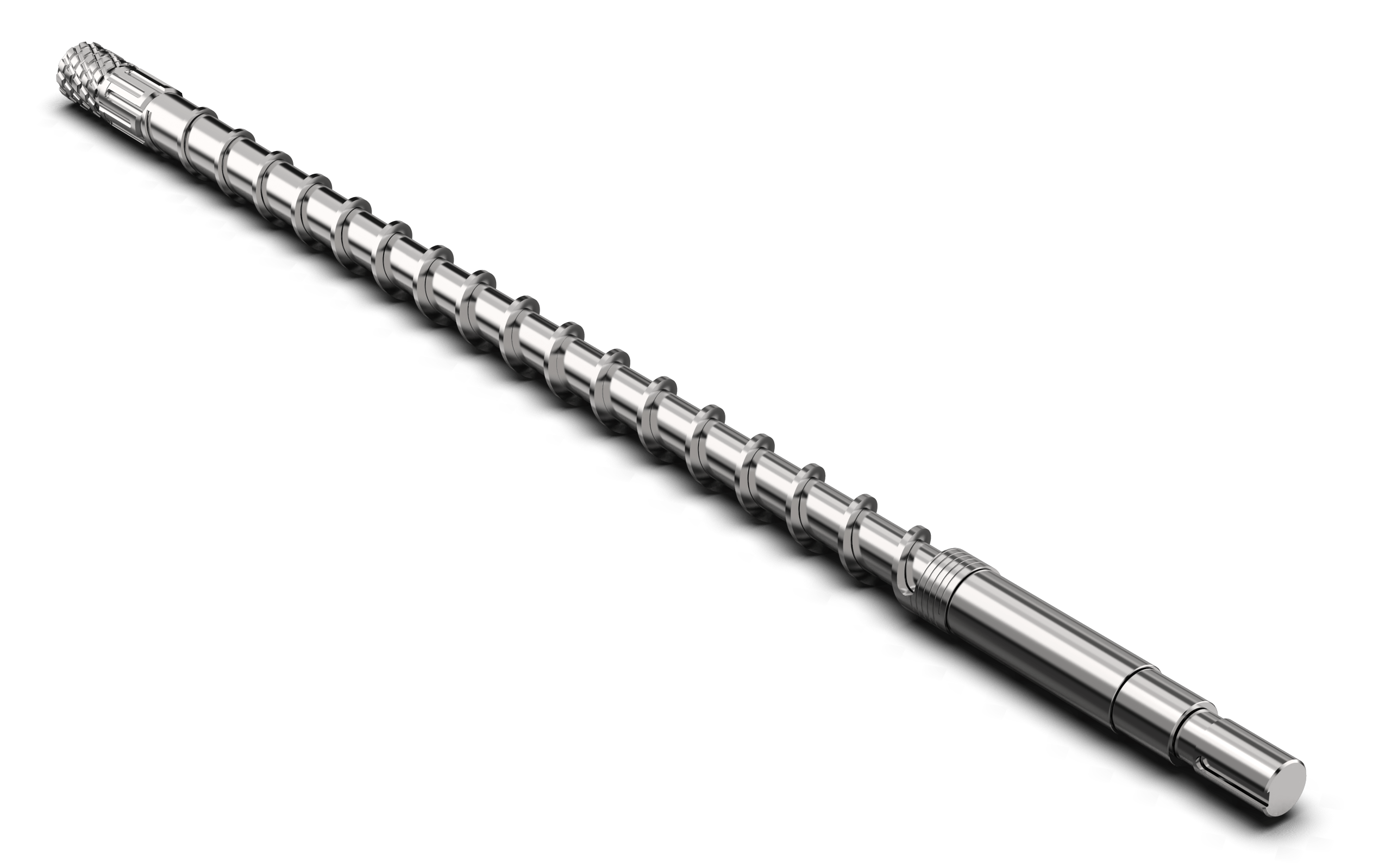

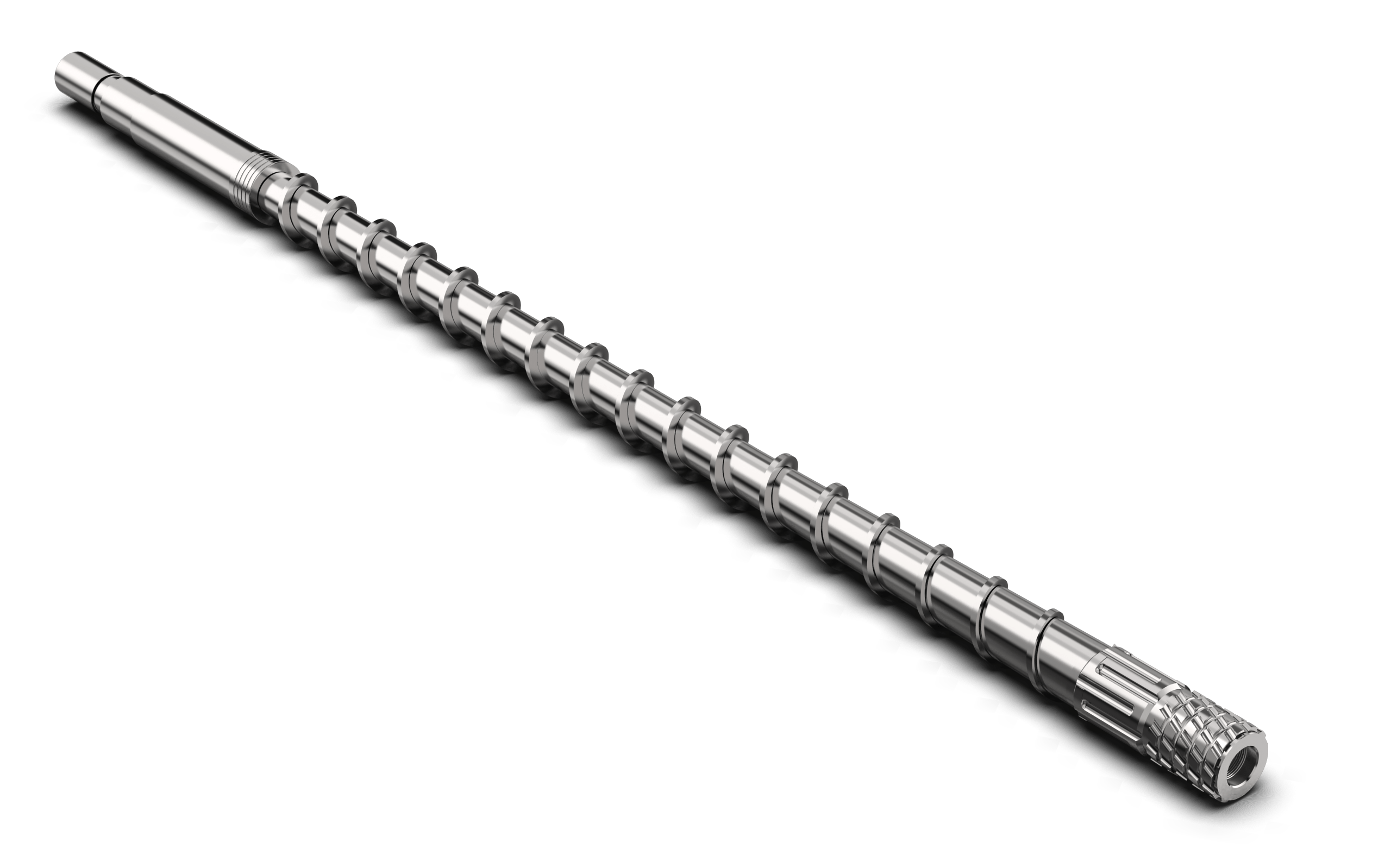

Hardened Screw

The hardening of screws is done by two processes - quenching and annealing. Quench hardening is the first process in which steel and cast iron alloys are hardened. The material - here the screw, is heated to a certain temperature and then rapidly cooled. This makes the screw hardened. The hardened screw is then tempered to reduce the brittleness that may have been increased from the quenching process. Another process is the annealing process. This is a kind of treatment in which heat alters the micro-structure of the screw which eventually causes changes in properties like strength, hardness, and ductility of the screw. Hardened screws use imported high-speed steel, after a series of quenching & annealing processes to achieve high toughness & hardness, especially suitable for high wearing production. The material that is used in H13 to achieve the surface hardness between 62-65 HRC. The available diameter sizes vary from 14mm to 120mm and the length can go up to 3 meters. At Shreeji Corporation, we have made our own grades of hardened screws that are SC-A, and SC1 to SC5. The applications are general raisin and engineering raisin that vary from 25% of glass fiber to 65% glass fiber.

- Product name – Through Hardened Screw

- Material – H13

- Available size – Dia 14 – 120 mm, length upto 3m long

- Surface hardness – 62-65 HRC

- Process method – Quenching & Annealing

Interested in Nitrided Screw, Bimetallic Screws, HVOF Coat Screw, Hardened Screw, Special Screw Manufacturer, Nitrided Barrel, Bimetallic Barrel, Special Barrel, Tie-Bar, Injection Head, RP Set, Nozzle, Conical Twin Screw & Barrel , Parallel Twin Screw & Barrel Manufacturing? Get Quote.

Production Process

-

Order & drawing confirm

-

Down Payment

-

Production

-

Hardening & Tempering

-

Inspection

-

Documents for clear customs

-

Packing & delivery

-

Balance

-

Inspection

-

Nitriding