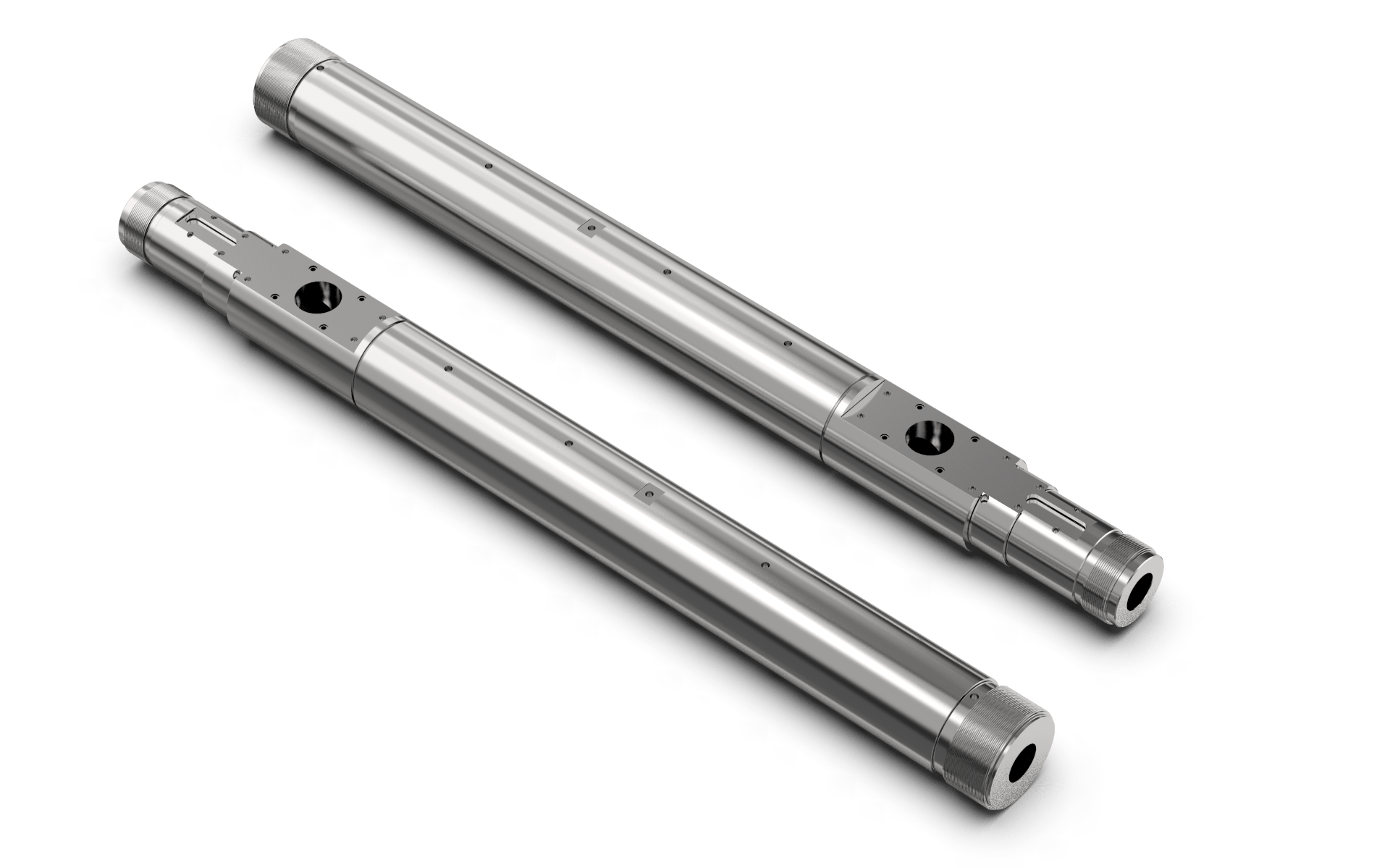

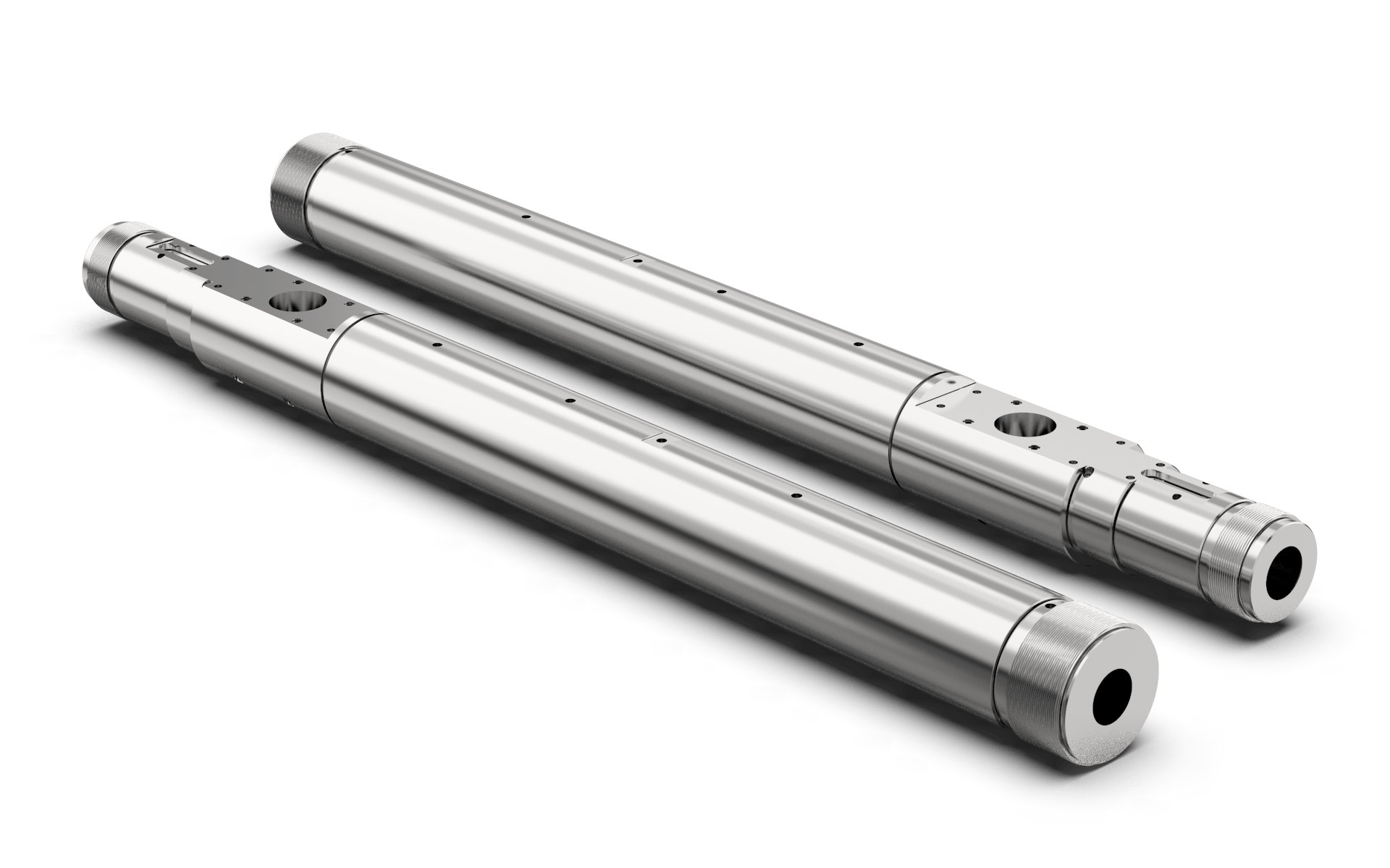

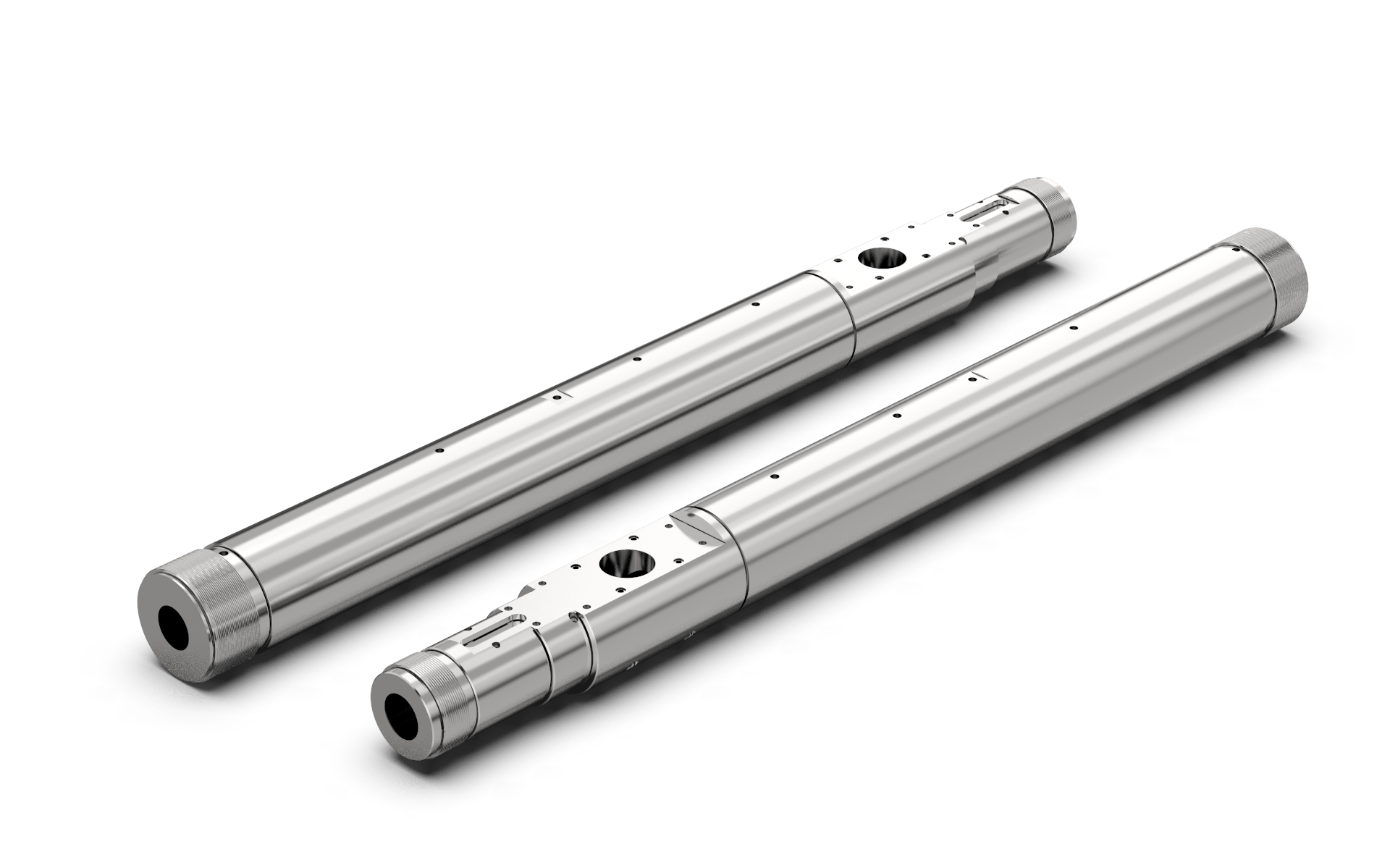

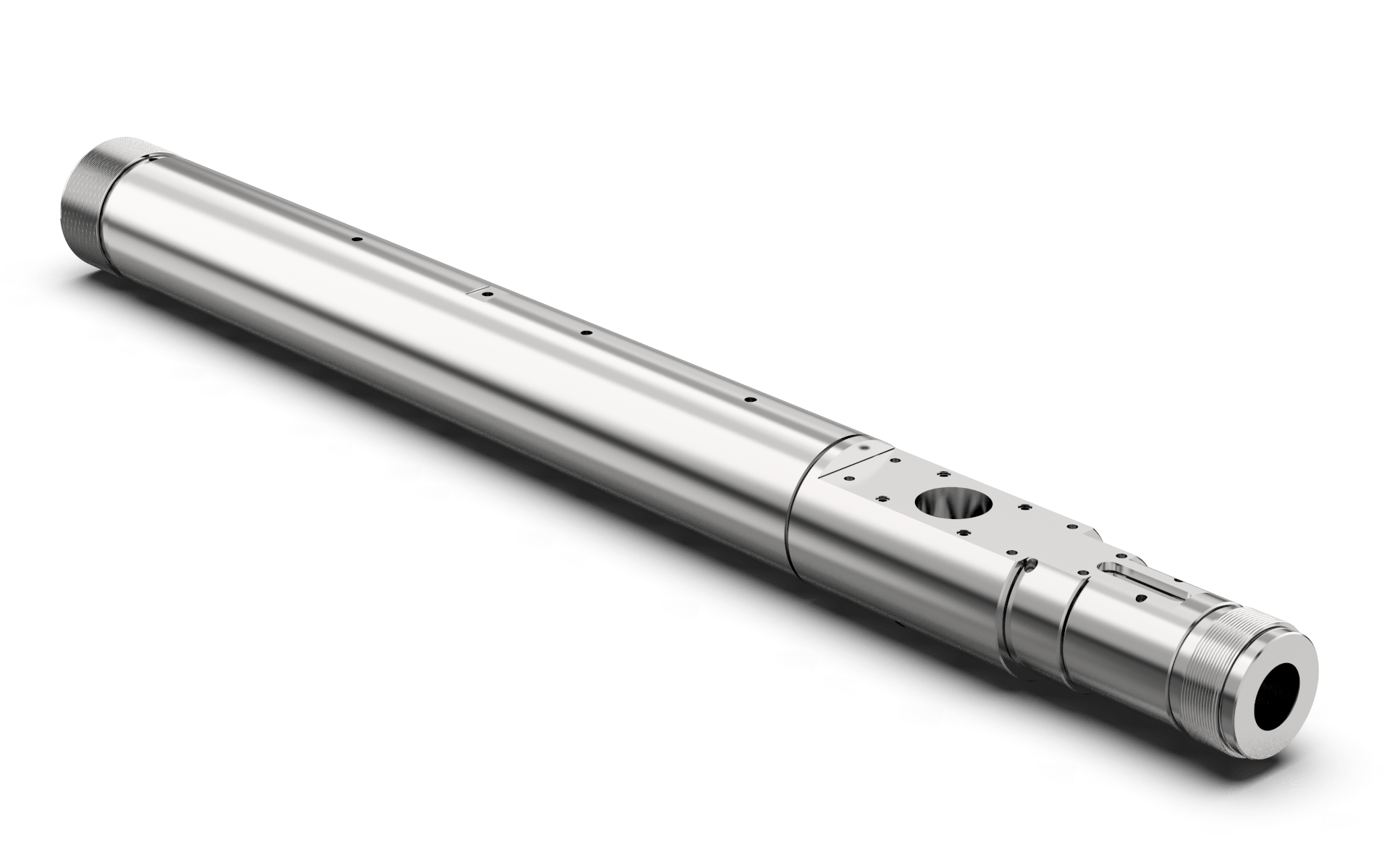

Bimetallic Barrel

A bimetallic barrel is made up of two metals or alloys. As the name suggests, in a bimetallic barrel, two metals are fixed together. A bimetallic barrel is used to increase the life of the entire screw and barrel. That is because a bimetallic barrel works better than a mono-metallic barrel. Bimetallic barrels are made in two metals - the base material and the coating material. That is why a bimetallic barrel lasts longer than a mono-metallic barrel. There are multiple applications of a bimetallic barrel. It can be used for corrosion formula, regrinding resin, calcium powder filling, additive fireproof materials, and additive plastic materials with less than 15% glass fiber. Special machines are adopted for hard-facing, with the alloy thickness over 1.5 mm, providing high surfacing bonding strength, dense textile & effectively improving the resistance of the barrel to abrasion, high temperature & corrosion. It helps extend the service life of the bimetallic barrel. The material that is used in a Bimetallic Barrel is EN41B with a coating of ni-based alloy. The available diameter sizes vary from 14mm to 200mm and the available length is upto 6 meters. The surface hardness achieved through the Gas Nitriding is 58-62 HRC.

- Product name – Bimetallic Barrel

- Material – EN41B + Coated (ni-based alloy)

- Available size – Dia 14 – 200 mm, length upto 6m long

- Surface hardness – 58-62 HRC

- Process method – Gas Nitriding + PTA

Interested in Nitrided Screw, Bimetallic Screws, HVOF Coat Screw, Hardened Screw, Special Screw Manufacturer, Nitrided Barrel, Bimetallic Barrel, Special Barrel, Tie-Bar, Injection Head, RP Set, Nozzle, Conical Twin Screw & Barrel , Parallel Twin Screw & Barrel Manufacturing? Get Quote.

Production Process

-

Order & drawing confirm

-

Down Payment

-

Production

-

Hardening & Tempering

-

Inspection

-

Documents for clear customs

-

Packing & delivery

-

Balance

-

Inspection

-

Nitriding