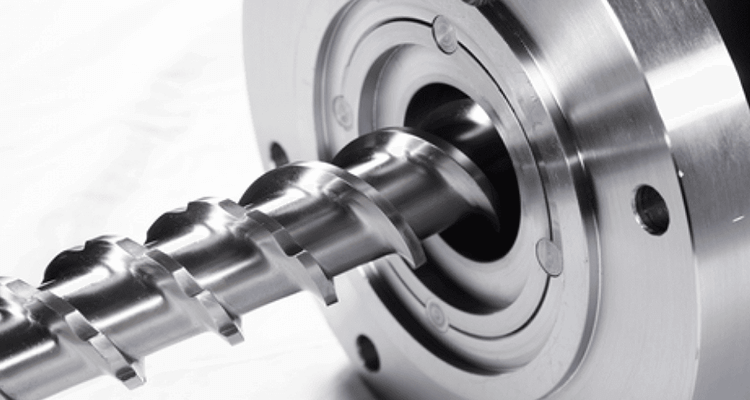

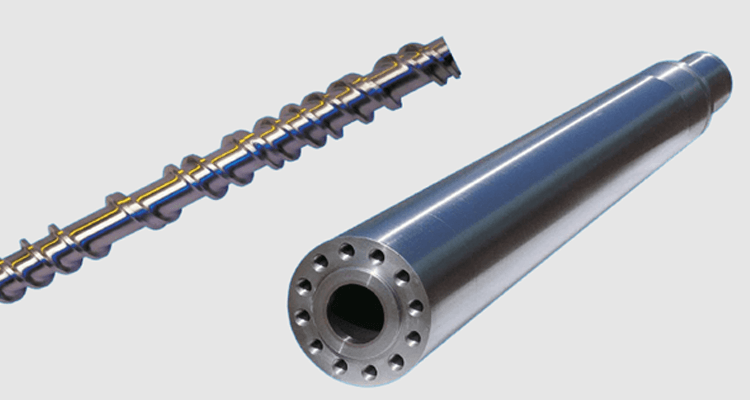

In the current competitive manufacturing environment, the proper functioning of plastic extrusion and injection moulding machines is reliant on screw barrels, which are critical components. The demand has increased for high-quality screw barrels, and now India, especially in cities like Ahmedabad, has become a powerhouse in the production and export of screw barrels and screw barrel-related industrial components.

So how has India come to dominate this niche industry?

Within this blog, we will examine why India and, in particular, cities like Ahmedabad, are a global epicentre of screw barrel manufacturing, what factors contribute to this dominance, and what makes Indian screw barrel manufacturers a unique asset in the global marketplace.

Strategic Growth of the Indian Manufacturing Sector

India’s evolution as a manufacturing giant was not an overnight phenomenon. The government has introduced several policies, such as “Make in India” and industrial clusters, which are experiencing growth in many states. These developments have created an enabling environment for mechanical and industrial engineering.

This shift in strategy has elevated the screw barrel manufacturing industry, enabling India to become a trusted partner in supplying precision-engineered components to both domestic and international customers.

Are You in Need of a Trusted Screw Barrel Manufacturer in India?

Find out how screw barrel manufacturers in India are setting new global standards!

Strong Supply Chain & Raw Materials

One of the most significant benefits Indian manufacturers have is easy access to high-quality raw materials, such as nitrided steel, bimetallic alloys, and hardened metals, which are specialized in high-wear screw barrels.

India’s supply chain infrastructure is also quite advanced, as it relates to raw materials and shipment of finished products to export countries or local destinations.

In other cities, such as Ahmedabad, this means there is vendor, machinist, and finisher expertise that forms an even more specialized supply chain.

Expertise in Customization & Engineering

All plastic processing applications have specific requirements, and manufacturers in India are skilled at producing custom screw barrel solutions. Whether it is for Injection Moulding, Extrusion, Blow Moulding or Recycling & Compounding Applications, engineers and technicians in India have years of experience and technical expertise on every project.

Companies that specialize in being a twin screw barrel manufacturer in Ahmedabad have an international reputation for providing developed components to meet global quality certifications (ISO, CE, and ASTM).

Need a Custom-Engineered Twin Screw Barrel for Your Extrusion Line?

Talk to the leading twin screw barrel manufacturers in Ahmedabad today!

Good Prices at a Good Quality

One of the main reasons that global buyers purchase from exporters of screw barrels in India is cost-effectiveness. They provide products that meet or exceed global standards, yet remain competitive in pricing due to:

- Lower labour costs

- Economies of scale

- Production technology

- Vertical integration for production & decoration

This pricing option makes buying screw barrels from India a no-brainer for global OEMs and machine manufacturers.

Ahmedabad: The Nucleus of Screw Barrel Innovation

When we consider screw barrel manufacturers in India, Ahmedabad is a key hub of excellence among hundreds of precision-engineered companies producing single and twin screw barrels for numerous industries.

Ahmedabad has earned this reputation due to:

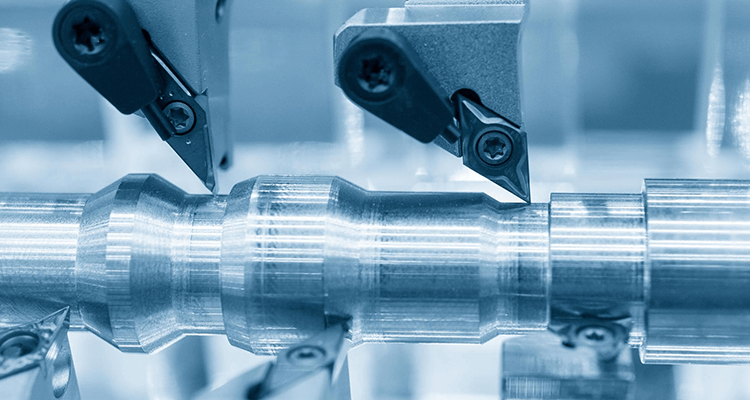

- World-class engineering talent

- Decades of machining experience

- Investment in CNC machining, heat treatment, and hard-chroming technology

- A dedication to innovation and continuous improvement

Come See Why Ahmedabad is the World Capital for Twin Screw Barrel Manufacturing!

Schedule a virtual tour of our facility.

The Global Surge in Demand for Plastic Processing Equipment

With the increasing demand for plastic products, typically packaging, construction, agriculture, and consumer items, the screw barrels market is growing rapidly.

India has leveraged a spike in production. Exporters of screw barrels in India are now shipping to over 50+ countries, including:

- USA

- Germany

- UAE

- South Africa

- Brazil

- Russia

The ability of Indian companies to provide ongoing and compliant products (REACH, RoHS, etc.) and a great deal of flexible international compliance has made Indian short-listed suppliers the procurement partners of choice.

Quality Assurance & Testing Infrastructure

Around the world, customers are demanding consistency and sustainability from machine components. Indian manufacturers understand this need and are investing in quality assurance processes that include:

- Hardness testing (Rockwell & Vickers)

- Metallurgical testing

- Heat treatment validation and verification

- Wear resistance testing

- Dimensional inspections (using CNC Coordinate Measuring Machines – CMMs)

These quality control checks ensure that every screw barrel performs as expected under extended high pressure and high temperature.

Do You Aim for Quality?

When purchasing screw barrels, connect with the best exporters of screw barrels in India and trust in a quality product for your long-term machine performance.

Industry 4.0 Transformation in Manufacturing

As we start with Industry 4.0, many Indian businesses are introducing automation, IoT, and smart monitoring into their processes. These changes will result in benefits such as:

* Production monitoring

* Predictive maintenance

* Increased machining accuracy

* Material usage reduction

These upgrades to technology can help screw barrel manufacturers in India with a competitive edge in the marketplace while having more flexibility and innovation.

Commitment to Sustainability

Environmental responsibility is increasingly becoming a top priority for global buyers. Indian manufacturers are beginning to adopt eco-friendly production processes, for example:

- Furnaces that use energy efficiently

- Recycling the waste produced while machining

- Green lubricants

- Renewables that reduce one’s carbon footprint

By seatbelting production practices that support sustainability in their mindsets, Indian exporters are not only trying to do right by the environment but are also embracing the environmental, social, and governance (ESG) concepts and practices of global business partners and clients.

Work with Environmentally Friendly Screw Barrel Manufacturers in India!

Do your supply chain proud with sustainability.

Strong Government Support & Export Incentives

Central and state governments in India have engaged with engineering and export-oriented industries to provide strong support, such as:

- Export subsidy/profits and tax breaks

- Upgrading technology (the TUFS schemes)

- Create industrial clusters and SEZs

- Help to participate in international trade shows

This government support cultivates competitiveness in Indian markets and helps to develop open channels for business connectivity.

Future Outlook: India’s Continued Dominance

With the way things are heading, India is in a great position to lead the screw barrel market for the foreseeable future. Investment will continue into:

- R&D

- Skilled workforce training

- Automation

- Global certifications

There is no doubt that India will be the best place for high-quality, lower-cost screw barrels for the world.

Conclusion: Why India Is Your Ideal Partner for Screw Barrels

From unparalleled engineering ability and flexibility to pricing and global quality, India provides every advantage a buyer could request in the screw barrel manufacturing business.

If you are a plastic machinery OEM, parts distributor, or plastic processor looking to improve your machines, consider working with a screw barrel manufacturer in India, especially a twin screw barrel manufacturer in Ahmedabad, for durability, precision, and value all in one place.