Today’s manufacturing industry is changing rapidly as technology improves, but the basis for success in industrial manufacturing has always been the same: precision, durability, and efficiency. An often overlooked component that enables consistent polymer processing (by means of plastic extrusion, injection moulding, recycling, and compounding) is the screw barrel. Polymer-based screw barrel manufacturers in India are rising dramatically, and as such, there is a growing demand for high-performance screw barrel systems.

In the search for an experienced and reliable screw barrel manufacturer in India, businesses have begun looking for partners rather than just suppliers. Today, they are looking for a manufacturer who offers innovative design solutions that meet their specific needs and can deliver them consistently. With manufacturing hubs emerging in cities like Ahmedabad, manufacturers are also searching for a well-established twin screw barrel manufacturer in Ahmedabad with a proven record of producing superior quality industrial products for export.

Let’s get a detailed overview of the specific uses of screw barrels, the various technological developments that are shaping the screw barrel manufacturing industry, and important factors to consider when choosing the right exporters of screw barrels to enhance your production efficiency and productivity.

Understanding Screw Barrels: The Core of Polymer Processing

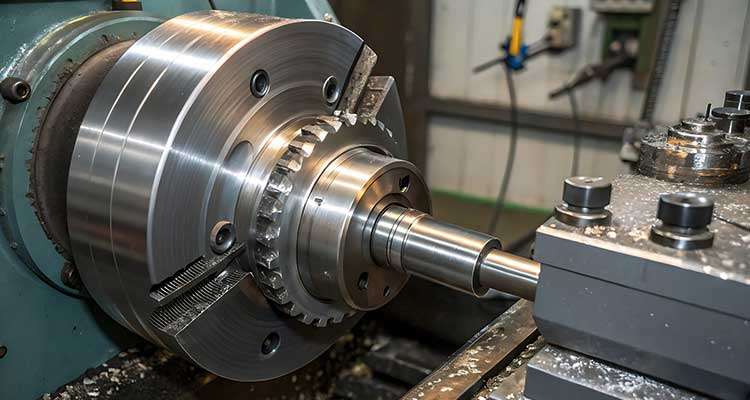

Screw barrels are important components of plastic processing machinery. The cylindrical mechanical screws are housed in them that provide rotation to melt, mix, and transfer (i.e., convey) the raw plastic material through the many different stages of plastic manufacturing.

Overview of Screw Barrels Functions

Feeding Materials & Conveying

Raw materials (e.g., polymer, additive and filler) are transported through a processing system very efficiently by the screw barrel conveyor.

Melting & Mixing

The screw barrels generate the heat and pressure necessary to melt the plastic and mix the materials uniformly.

Pressurising & Shaping

The screw barrel provides the pressure and continuous movement of the molten plastic towards the mould or extrusion dies.

The screw barrel manufacturer in India has years of experience and adheres to stringent engineering tolerances to achieve maximum productivity, durability, and energy efficiency.

Looking to Enhance your Machinery Performance with High-Precision Screw Barrels?

Partner with industry-leading experts who deliver engineered solutions tailored to your production requirements.

The Growing Demand for Screw Barrel Manufacturing in India

Indian manufacturing is becoming well known throughout the world for its production of both plastics (polymer-based products) and polymers (raw materials). There are many industries, including automotive, packaging, construction, medical device, and electronics; these will continue to rely heavily on screw barrel technology as they expand.

Reasons for the growth of the market:

- Rapid Industrial Growth

The manufacturing sector in India is growing rapidly, thus creating a need for high-performance screw barrel components.

- Initiatives from the Government

Government sponsorship of domestic production of machinery and components has fostered a positive environment for many screw barrel manufacturers.

- Export Markets

International manufacturers of screw barrels looking for suppliers often prefer to partner with established exporters not only for cost reasons, but also for quality assurance and customisation options.

- Technical Advances

Newer screw barrels use improved coatings, wear-resistant materials, and allow for more precise machining, which enables a longer service life and higher operating efficiencies.

A high-quality screw barrel manufacturer in India will have adopted new engineering technologies and applied stringent quality standards consistent with the global marketplace to meet the high demands of today’s manufacturing environment.

Experience Precision Engineering Excellence

Invest in screw barrels manufactured with advanced metallurgy and CNC technology to reduce downtime and maximise productivity.

Twin Screw Barrels: Revolutionising Polymer Processing

Due to their superior mixing capabilities, enhanced throughput, and flexibility, the popularity of twin screw barrels is increasing across industries. In Ahmedabad, one of the leading twin screw barrel manufacturers provides technologically advanced products that are used in high-performance applications.

Benefits of Twin Screw Barrels

Improved Mixing Ability

Twin screw systems provide thorough mixing of polymers and additives, resulting in improved quality of the final product.

Improved Productivity

Twin screw systems provide increased speeds and improved distribution (or dispersion) of materials.

Multiple Applications

Twin screw barrels can be used for a wide variety of manufacturing processes, including compounding, extrusion, and recycling.

Improved Thermal Control

Twin screw barrels allow for better regulation of temperature; therefore, less material damage occurs.

Many industries, including pharmaceutical, food packaging, and high-performance plastics, benefit from twin screw barrel systems for consistent and predictable production results.

Boost Your Manufacturing Speed & Output

Switch to advanced twin screw technology and achieve superior material blending, faster throughput, and reduced processing time.

Why Ahmedabad is Becoming a Leading Manufacturing Hub

In the last 10 years, Ahmedabad has emerged as a hub of industrial machinery production, with suppliers in this market trusted globally for their ability to produce quality products at reasonable prices while maintaining an excellent track record for exporting products overseas.

Here are some key advantages of manufacturers located in Ahmedabad:

Skilled Engineering Labour Force: Ahmedabad’s population includes a large number of skilled technical workers with expertise in metal fabrication, machining, and mechanical engineering, who can be utilised by companies in the Ahmedabad area.

Modern Manufacturing Infrastructure: Many modern manufacturing facilities in this area utilise state-of-the-art CNC equipment, sophisticated heat treatment systems, and high-precision laboratory quality control procedures.

Export Production: A majority of the suppliers in this area produce products for export and comply with the global quality standards required by the exporting country.

For example, one of the best companies that are twin-screw barrel manufacturers in Ahmedabad uses both traditional hand-crafting methods and advanced robotics to produce reliable, durable products.

Looking to Partner with Globally Trusted Manufacturers?

Collaborate with manufacturers delivering world-class screw barrel solutions backed by international quality certifications and engineering expertise.

Applications of Screw Barrels Across Industries

Screw barrels are a practical solution and a very effective tool across industries.

- Plastic Extrusion: This application includes the production of sheets, films, tubings and other profiles.

- Injection Moulding: This system includes the melting of plastics and the injection of melted plastics into a variety of moulded parts such as automotive parts, containers, and consumer products.

- Rubber Processing: Rubber is mixed with additives and fillers using screw barrel technology.

- Recycling Plant Applications: Commercial applications utilising screw barrels as part of the reprocessing of plastic waste to create new raw materials.

- Food Processing: The use of twin screw barrels for mixing and processing food ingredients is widespread.

Selecting a qualified manufacturer of screw barrels will assure compatibility with a wide variety of machine configurations and industry applications.

Want to Find the Perfect Screw Barrel for Your Industry?

Whether you operate in extrusion, moulding, or recycling, discover customised screw barrel solutions designed to match your industrial needs.

Key Materials Used in Screw Barrel Manufacturing

The performance and durability of screw barrels are primarily determined by the type of material that was used to manufacture the original assembly.

Materials Commonly Used to Construct Screw Barrels:

- Nitrided Steel: Provides excellent wear and corrosion resistance.

- Bimetallic Barrels: Provide greater resistance to abrasives and corrosives.

- Alloy Steel: Provides high strength and thermal stability for demanding applications.

The leading exporters of screw barrels utilise advanced metallurgy, surface treatment and/or coatings to enhance the operational life and efficiency of their screws and barrels.

Looking to Invest in High-Performance Materials?

Choose screw barrels manufactured using premium-grade alloys and coatings for maximum durability and consistent performance.

Advanced Manufacturing Technologies Used by Modern Screw Barrel Manufacturers

While consistently improving screw barrel systems, many of the top screw barrel manufacturers focus on developing new technologies to create reliable products.

- Precision CNC Machining: Provides an exact fit and precision-ground finish.

- Plasma Coating & Hard Facing: Increases wear-resistance and decreases maintenance costs.

- Vacuum Heat Treatment: Increases hardness and structural stability.

- Using CAD & Simulation Software: Provides engineers with a way to design optimum screw geometries to enhance performance.

A leading technological screw barrel manufacturer in India has developed a state-of-the-art manufacturing process to merge reliability with innovation in order to give customers an average of 20% more quality, value, and performance than those manufactured anywhere else.

Want to Experience Next-Generation Manufacturing Technology?

Upgrade to precision-engineered screw barrels built with modern CAD design and advanced heat treatment processes.

Conclusion

A screw barrel is the major component of the polymer and plastic manufacturing industries globally, and manufacturers need to find and source high-performance machinery parts from credible manufacturers; the manufacturers should be technically advanced.

India’s advancing manufacturing has emerged as one of the largest producers of screw barrels globally. Many industries searching for a reliable and respected screw barrel manufacturer in India, a top-rated manufacturer of twin screw barrels, or a trusted source for international screw barrel exports can take advantage of working with a company that has experience, is innovative and uses high-quality materials.

Precision screw barrel systems have shown to increase productivity, lower production costs, create better quality products and offer a path toward sustainable growth.