Have you ever had a fan or a toy break down too soon? It is annoying, right?

Now imagine the same thing happening in a big plastic factory. Machines stop working. People stop working. Orders get delayed. And all of this because of one part inside the machine that wore out too fast.

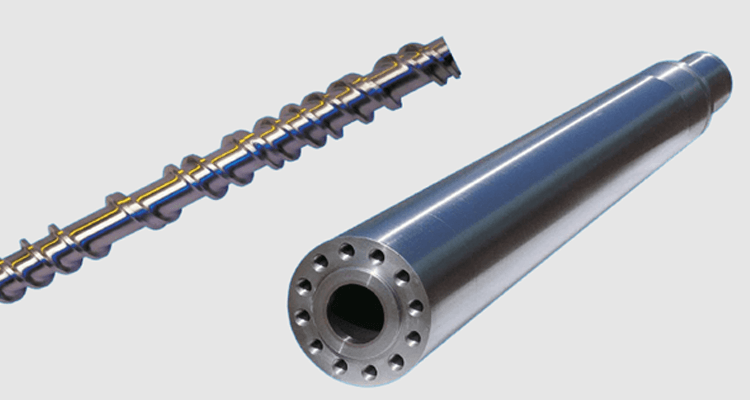

That tiny part? It is often the screw barrel—a very important piece in plastic processing machinery.

But guess what? The good news is—new and stronger materials are now being used to make these parts last longer. And today, we are going to talk about them. Do not worry—it is going to be super simple to understand.

Let us begin!

Why Do Screw Barrels Wear Out So Fast?

Imagine a spoon stirring thick, hot honey all day, every day. That is how screw barrels work inside plastic machines.

They have to deal with:

- High heat – just like boiling water.

- High pressure – like squeezing toothpaste from the end.

- Rough materials – some plastics have tiny stones or glass in them!

And not just that—some plastics are also acidic or chemically active, which slowly eats away the metal. This is called corrosion.

Now think—if this keeps happening every day, what will happen?

The screw barrel gets damaged. Machines stop. Factories lose money. That is why every screw barrel manufacturer in India is always looking for ways to make better, longer-lasting products.

What Are Bimetallic Alloys and Coatings?

Okay, so how do we make screw barrels stronger?

We use something called bimetallic alloys and advanced coatings.

Sounds tricky? Let us break it down.

Bimetallic means “two metals.” It is like a sandwich—one strong metal on the inside and another very tough metal on the outside. The inside gives strength. The outside fights damage.

And then there are coatings—like a raincoat for the screw barrel! These include special treatments like nitriding (which makes the metal very hard) and spray coating (which adds a shield on top).

Together, these help the screw barrel stay strong, even when the job gets tough.

How Do These New Materials Work?

Let us say you are cooking. You use non-stick pans, right? Because they last longer and food does not stick.

Same logic here.

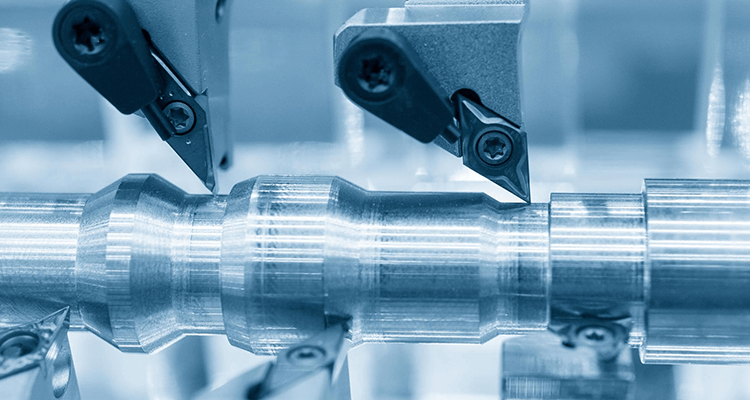

We use smart techniques like:

- Spin casting: where hot metal is spun inside a barrel to form a hard lining.

- Sleeve fitting: where a tough tube is placed inside the barrel.

- Nitriding: where the surface is heat-treated to become super hard.

These new materials:

- Do not crack easily

- Do not wear out fast

- Can handle recycled plastics (which are rougher)

- Can fight acids and chemicals better

This means the machine can work with more types of plastic and for a longer time!

Real-Life Results: Less Trouble, More Work Done

Here at Shreeji Corporation, we have seen some amazing changes.

One factory came to us and said, “We have to change screw barrels every 6 months.” We suggested our bimetallic barrel with special coating.

Guess what?

Now, they change it every 18 months! That is 3 times longer.

Another customer told us, “We keep stopping the machine for repairs.” After using our advanced coated screws, their machine ran smoother and had less downtime.

Can you imagine how much time and money they saved?

That is the magic of better materials.

How Indian Manufacturers are Leading the Game

You will be proud to know that many screw barrel manufacturers in India are now using these smart materials.

Especially in Ahmedabad, where we are based, the industry is growing fast. Many customers, not just in India but also from other countries, are asking for our products.

Why?

Because we understand how to mix science and skill. We use the latest methods. And we custom-make parts for each customer’s unique need.

From high-tech machines to trained people—we have it all at Shreeji Corporation, a trusted screw barrel manufacturer in Ahmedabad.

So, What Should You Do?

If you run or manage a plastic factory, here is a simple tip:

Talk to your screw barrel manufacturer. Tell them:

- What kind of plastic you process

- How often you change parts

- What problems you face

Based on this, they (or we!) can suggest the right alloy or coating. Some factories need anti-wear strength. Others need anti-corrosion power. Some need both!

We also suggest regular check-ups and small upgrades over time—just like servicing your car. That way, your machine keeps running like new.

Stronger Materials, Stronger Machines

So what did we learn today?

Machines need strong hearts. And in plastic processing machinery, the screw barrel is just that. With the rise of bimetallic alloys and advanced coatings, we are entering a new age of longer-lasting and better-performing machines.

At Shreeji Corporation, we are proud to be one of the leading screw barrel manufacturers in India. And right here in Ahmedabad, we are making a difference with every product we build.

We believe in smart work, strong parts, and happy clients.