That is the same conversation most factories are having these days. Resin prices have gone up. Transport costs fluctuate. Every customer wants “better rates,” even when the numbers don’t make sense anymore. Teams look at cycle times, molds, scheduling, and manpower. They try to fix every visible variable on the outside.

Yet, the truth is that most production teams quietly agree on this:

A lot of the losses begin inside the screw barrel.

Not the mold. Not the resin supplier. Not the machine.

The screw barrel.

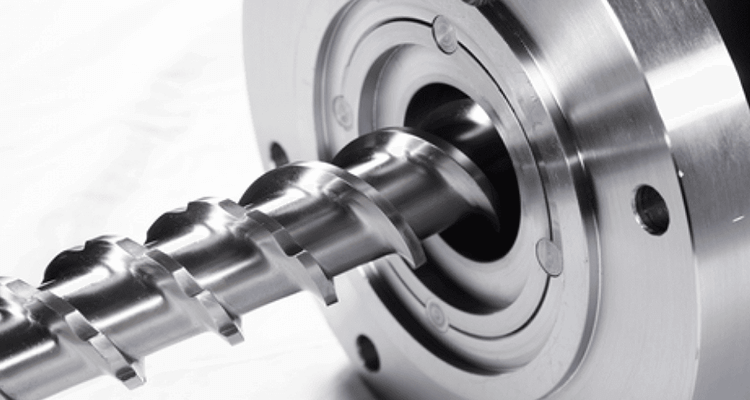

This one component determines how material melts, mixes, and stabilizes. And when it starts to wear out, or was never engineered right for your resin in the first place, the whole line begins losing money in small, nearly invisible ways.

This is why more plants have started reaching out to engineering-focused suppliers such as Shreeji Corporation, known among industries as trusted exporters of screw barrels for injection molding and extrusion. The industry finally realised that improving melt quality is one of the fastest ways of controlling costs in the case of a rise in raw material prices.

Here are the takeaways most factories discover once they focus on the barrel.

1. Wastage Usually Begins Before the Mold Even Opens

Splay, burns, short shots, black specs, and inconsistent fills are just a few of the defects that generally point back to one thing.

An unstable melt inside the screw barrel.

A worn screw, a barrel that heats unevenly, or a profile that doesn’t match the resin forces operators to make constant adjustments. These are symptoms of internal instability. And once the melt is unstable, the mold cannot produce a consistent part. Therefore, it becomes important not only to care for the metal screws but also to optimize their use.

2. A New, Well-Designed Screw Barrel Greatly Reduces Waste

Factories that substitute old or generic barrels with high-grade EN41B nitrided barrels often report immediate improvements. Purging reduces. The melt stops discoloring. Back pressure becomes steady.

These changes matter when resin is expensive.

This is the very reason why skilled screw barrel suppliers or technically strong screw barrel manufacturers are in demand. Industries need engineering behind their barrels, not just a metal component.

Working with teams like Shreeji Corporation, which are established exporters of screw barrels, helps factories choose the right metallurgy and geometry for their material.

3. A Better Screw Barrel Quietly Reduces Electricity Consumption

A properly engineered screw barrel will melt material more efficiently.

Heaters behave less aggressively.

Motor load reduces.

Temperature fluctuations decrease.

Some automotive and packaging units reported noticeable reductions in electricity consumption with the upgrading of barrels, even without a change in the cycle time.

Energy savings are slow and steady, but very real over a year.

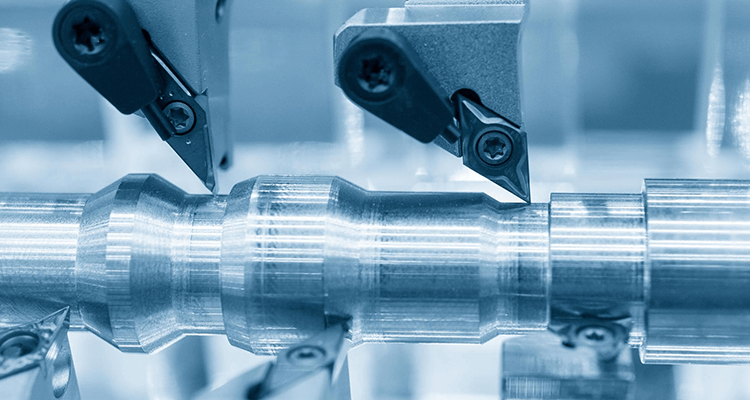

4. Output Improves When Screw Geometry Matches Your Resin

There is no “standard” melt behaviour.

ABS, PP, Nylon, and filled materials respond all differently to heat and pressure.

Melting is quicker, and homogenization is cleaner when the screw barrel is designed for the resin actually used in production.

That’s where technical partners like Shreeji Corporation excel. Their knowledge of resin behaviour is what makes their work so important as Screw barrel manufacturers and also global exporters of screw barrels to the factories that need stable output.

5. Barrels Wear Long Before They Look Worn

Most factories believe that they are only supposed to change the barrel when it shows visible damage.

In reality, performance starts dropping much earlier.

The early signs include:

- slight temperature fluctuations,

- extra purging,

- yellowing of the melt,

- inconsistent pressure,

- and minor flow variations.

These little things add up unbeknownst to anyone. By the time the factory isolates the true cause, several months of productivity are already lost.

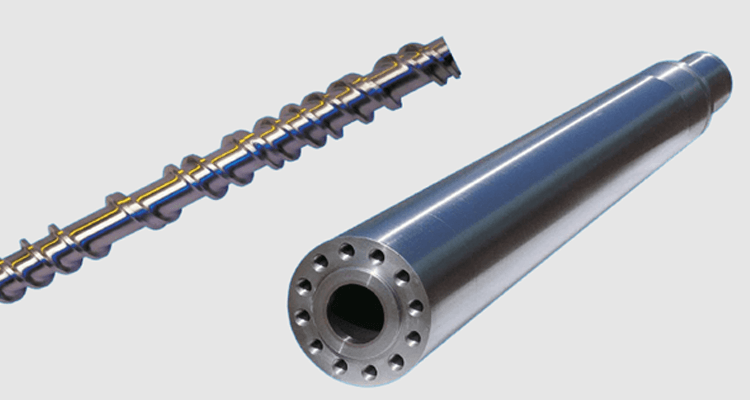

6. Metallurgy Matters More Than Most Teams Think

The main factors that strongly influence how long an EN41B nitrided steel screw barrel performs at peak level are uniform hardness and precision machining. These factors decide how well the barrel handles fillers, temperature cycles, and long production hours.

Companies like Shreeji Corporation, esteemed throughout India and abroad as a high-quality screw barrel supplier, put great emphasis on metallurgy. One of the major reasons for their inclusion among the leading exporters of screw barrel is this consistency.

7. Lower Rejection Starts With a Stable Melt

A rejected part consumes resin, electricity, machine hours, and operator time.

Most defects are due to unstable melt, not the mold.

Rejection rates fall rapidly when a quality screw barrel stabilizes melt formation. Many automotive and packaging units have witnessed a drop from 8–10 percent rejection to 2–3 percent after upgrading.

Operators can feel the difference within days. The parts look cleaner, and the machine becomes easier to run.

8. Resin-Specific Screw Design Pays for Itself Faster Than Machine Upgrades

Buying a bigger machine looks like a solution, but it brings higher electricity bills, more tonnage, and more complexity.

A resin-specific screw barrel gives faster returns because of the following reasons:

- melt consistency

- mixing

- flow

- throughput

- and cycle stability

This is one of the key reasons factories prefer to work with Shreeji Corporation. Their engineering-focused approach as screw barrel manufacturers allows companies to achieve more output from the equipment they already own. Here are a few tips on how to maintain screw barrels for better and longer life.

9. Operators Do a Better Job if the Melt Behaves

When the melt is predictable, operators make fewer adjustments, purge less, and rarely chase temperature swings. The shift-to-shift variations decrease, and the line becomes calmer and more controlled in general.

A good screw barrel reduces operator dependency, which is a quiet but significant cost saving.

10. In a High-Cost Market, Efficiency Beats Scale

Increasing capacity is costly. Improving efficiency is strategic.

A high-performance screw barrel improves melt quality, lowers scrap, reduces energy usage, and stabilizes output without changing machines.

That’s why modern factories update their barrels through technically strong partners like Shreeji Corporation, who have built up a reputation as dependable exporters of screw barrels for both domestic and global industries.

Final Thought for Manufacturers

If margins are tight and material costs keep going up, start with the one place that affects every part you make.

The screw barrel.

A barrel upgrade usually yields faster results than a machine upgrade.

Better melt quality means better output, fewer defects, and higher profitability.

Companies trust Shreeji Corporation, not just because they are reliable exporters of screw barrels, but because they understand how to engineer barrels that improve day-to-day production in real factories.