In the thick of India’s industrial world, there lies a very compelling narrative with compelling qualities of resilience, precision manufacturing and aspirations set at a global level. This narrative is shown by the twin screw barrel manufacturer in Ahmedabad, and also by the complete network of screw barrel manufacturers in India & exporters of screw barrels. Today, this area is no longer a small niche in mechanical engineering; it has become the backbone of India’s manufacturing capability, specifically within the plastics processing sector, Automotive Parts, Construction Equipment, Packaging Machines, and many more.

This blog will help to bridge the divide between artisan craftsmanship that exists at the local level and the wider world market, discussing some of the modernisation and innovative trends that are developing in the industry, as well as giving insight into what this will mean for businesses and the economy.

The Backbone of Plastic Processing: What Are Screw Barrels & Why They Matter

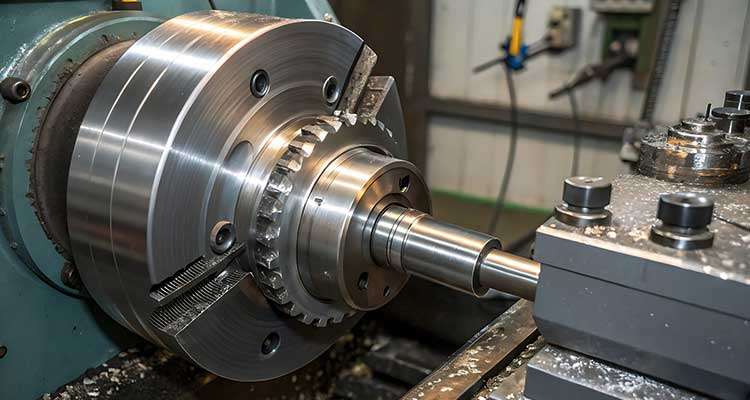

The screw barrel seems initially a modest industrial component – it is basically a metal tube with an internal helical screw used in injection-mould machines and wire extrusion. However, screw barrels are actually precision parts that strongly impact production costs, machine efficiency, and product quality in various industries, such as food processing and plastics.

In particular, the twin-screw barrel consists of two intermeshed screws that mix, convey and homogenise materials through the use of controlled pressure and elevated temperature. These distinctive features enhance material consistency and throughput, making them necessary for the fabrication of highly engineered polymers and other expensive, highly engineered products.

The demand for these types of components has continued to rise globally as global plastic consumption for packaging, building materials, consumer goods, and automotive industries continues to grow. Since extrusion and moulding machines are important tools for these manufacturing industries’ continued growth, they, in turn, rely heavily on twin-screw barrel manufacturers in India.

Ahmedabad: Strategic Hub for Twin Screw Barrel Production

Ahmedabad has long been recognised for its rich textile tradition and has now become a major manufacturing hub in India for the production of twin-screw barrels. There are many companies located in the Ahmedabad region that manufacture high-precision screw barrels, supplying both Indian customers and international customers.

From Local Workshops to Global Markets: Exporters of Screw Barrels Driving Growth

The advancement of the screw barrel manufacturers in India has not only been about the number of screw barrels manufactured, but it has also been about global integration. For example, Indian exporters of screw barrels are exporting screw barrel components to over 50 countries, and many of these countries include major markets such as the US, Germany, UAE, South Africa, Brazil and Russia.

This reflects some of the advantages created by the momentum of exporting screw barrels:

The Rise of Global Recognition

- Compliance with Quality: Many manufacturers in India are now following international standards (REACH and RoHS), which enable them to secure global contracts.

- Investing in Testing & Assurance: By investing in state-of-the-art testing facilities for hardness, wear resistance and dimensional accuracy, Indian manufacturers are able to provide consistency and reliability in their products.

- Capability to Customize: By being able to customize barrels for specific types of extrusion machines and applications, Indian exporters have a significant competitive advantage.

Ready to Scale Your Production Line?

Connect with leading exporters of screw barrels in India to explore custom manufacturing and quality-tested components for your industry.

Industry Trends: What’s Shaping Modern Screw Barrel Manufacturing

Technology, sustainability and strategic business thinking are just a few of the influences behind the evolution of precision manufacturing, over and above demand.

Industry 4.0 (Smart Manufacturing/IIOT)

More manufacturers are implementing CNC (Computer Numerical Control) machining, IoT (Internet of Things) enabled monitoring, and automated predictive maintenance. This has resulted in smart upgrades that:

- Reduced lead times.

- Improved the dimensional precision of parts.

- Decreased scrap rates.

- Improved energy efficiency.

In addition to improving product quality, integrating digitally into manufacturing enables Indian manufacturers to compete better on a global level.

Make Your Supply Chain Future-Proof!

Learn about screw barrel technologies (enabled by Industry 4.0) that offer stability, efficiency and scalability.

Sustainability/Responsible Manufacturing

Historically, manufacturing has been resource-intensive. Today, leading manufacturers in Ahmedabad and other regions are adopting:

- Energy-efficient heat treatment furnaces.

- Recycling of machining scrap.

- Eco-friendly lubricants and clean energy.

- Environmentally friendly packaging.

The movement towards these practices represents a broader commitment to environmental, social and governance (ESG) principles that many global manufacturers find important when buying from manufacturers.

Resiliently Commit to Green Engineering!

Look for and partner with manufacturers that utilize environmentally responsible practices and support sustainable supply chains.

Commercial Impact: How Screw Barrel Manufacturing Fuels Broader Sectors

Though screw barrels are highly specialized components, they actually impact many different sectors of the manufacturing industry. We’ll look at just a few heavy industries that directly benefit from the use of screw barrels.

Packaging & Consumer Goods

The growth of e-commerce is creating a greater need for lower weight/death plastics in both packaging and consumer products. As a result, the demand for high-performance extrusion components is increasing. Therefore, the packaging and consumer goods sectors will continue to experience increasing demand for high-performance extrusions.

Construction & Infrastructure

Modern buildings and utility systems rely on the use of precision-made extruders and screw barrels to form PVC pipes, profiles, and sheet materials.

Automotive & Industrial Equipment

The majority of automotive polymer parts (e.g. dashboard components, weather seals, etc.) utilize either barrel-enhanced extrusion or barrel-enhanced moulding within their production.

The combination of all three of these sectors illustrates the important economic value that hubs of precision manufacturing, like Ahmedabad, bring to modern society.

Final Thoughts: Craftsmanship Meets Commerce

The development of the twin screw barrel manufacturers in Ahmedabad and the larger network of such manufacturers and exporters throughout India is not just an industrial success for these companies; rather, it shows the power of precision engineering and effective strategic market positioning to turn local talent into a product that has a global reach.

Here, we can see how these companies combine traditional machining capabilities developed over many years with cutting-edge manufacturing technology. With the ever-increasing global need for superior-quality components, this growth reinforces India’s place on the industrial map.

Whether you are a manufacturer looking for reliable components, an investor seeking opportunities in growing sectors of the industrial marketplace, or an engineer with an interest in precision parts, now is a very exciting time to be involved with the emergence of screw barrel manufacturers in India.

Ready to Elevate Your Machinery’s Performance?

Connect with top-rated screw barrel specialists and twin screw barrel manufacturers in Ahmedabad today – and take a step toward manufacturing excellence.